JFE upgrades Japanese large-diameter pipe mill with welding technology from SMS group

Fully digitalized welding process and process data monitoring take pipe welding to the next level

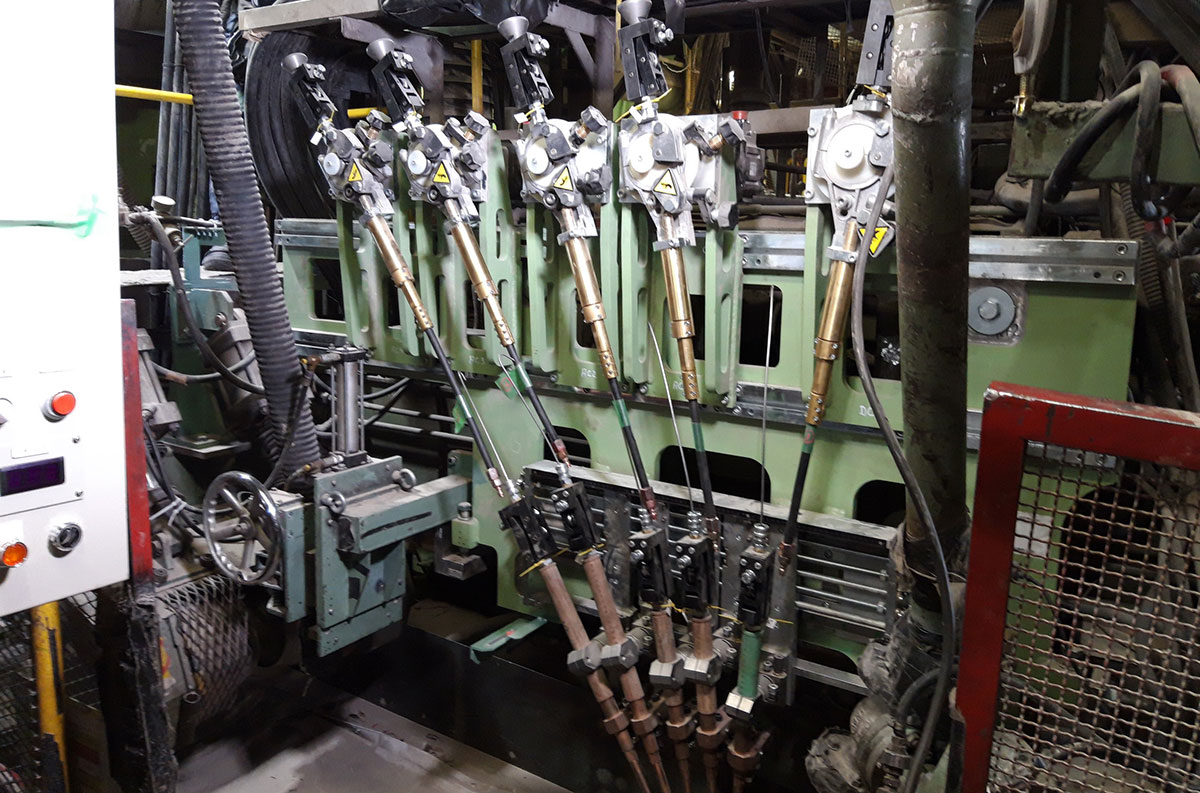

JFE Steel Corporation has produced the first pipe at its Fukuyama works in Japan after the successful revamp of its submerged arc welding (SAW) stands by SMS group (www.sms-group.com). The revamp included five-wire submerged arc welding heads, digital inverter welding current sources (PERFECT arc®), and a measured data recording, monitoring and evaluating system.

JFE's large-diameter pipe mill, located in western Japan, has been in operation since the beginning of the 1970s. As JFE has developed its own proprietary submerged arc welding stands at that mill, the company can today build on welding parameter data and know-how from more than 50 years of operation. Consequently, the current revamp project focused primarily on enhancing the repeatability and furthering the development of the welding parameters.

At the same time, the revamp of the welding technology was aimed at enabling the development of new welding parameters that would make it possible to vary the welding speed and the energy input into the weld seam. These capabilities are particularly important when welding high-strength steels and steel for in-service temperatures well below freezing point (-10°C to -20°C).

To ensure that the revamp fully meets JFE's requirements, prior welding tests were carried out. Jointly with the welding specialists from JFE, SMS group welded longitudinal-seam pipes from material provided by JFE for this purpose on a five-wire submerged arc welding stand at the Technical University of Berlin in Germany. The results of these welding tests showed that the SMS group technology is able to ensure compliance with JFE's exacting demands.

Given the fact that JFE had previously used only four wires in submerged arc welding, the available space for the new five-wire welding heads was another challenging task of the project. SMS group solved this challenge by developing a more compact design for the new five-wire welding heads, without any compromise in terms of stability and ease of welding head adjustment and maintenance.

As well as upgrading the outside welding stands from four-wire to five-wire welding, the old transformer-based welding current sources were replaced with the new PERFECT arc® digital current sources from SMS group.

In addition, SMS group established an interface with JFE's manufacturing execution (MES) and plant monitoring system (PMS). These systems exchange production and process parameters during welding to optimize production evaluation, production planning and quality assurance. A special focus of the data transfer solution was to incorporate the data collected in the past into the new systems.

With this upgrade, JFE is consolidating its position as a technology leader in the global market for large-diameter longitudinally welded pipes. Thanks to the higher welding speed and reduced error rate, the new technology not only boosts productivity but also ensures that, while maintaining the same speed, less heat – in other words, energy - is input into the material. From the latter JFE benefits particularly when welding high-strength steels.