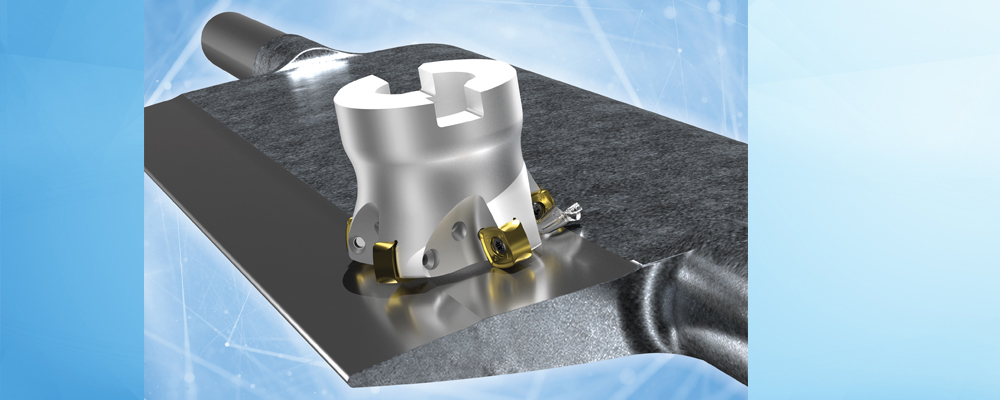

THETAtec 25N Feed: High feed milling redefined

Boehlerit has already set standards with its positive high feed systems. Now the company is expanding its high feed portfolio and launching its new tool concept on a negative basis. Like its positive systems, this innovative THETAtec 25N Feed tool system enables higher cutting rates and thus maximum performance and efficiency in a single application. High-performance cutting (HPC) has become established for machining operations with high removal rates, such as those required for roughing steel, cast iron and stainless materials. Maximum feed rates maximise the volume of chips removed and thus reduce machine occupancy times. This is advantageous in terms of the increasingly cost-relevant energy efficiency of processes and creates additional production capacity. High-performance cutting thus brings productivity increases and measurable cost reductions at the same time. With the new THETAtec 25N Feed, Boehlerit now also offers another high-end tool system for this machining strategy. In contrast to its positive counterparts from Boehlerit, the THETAtec 25N Feed now uses a negative cutting insert concept with 8 realistically usable cutting edges for the first time, without compromising on performance, as a great deal of knowledge has been gained in high feed applications over the years. During the development of this new system, the best-implemented simulation software was used in order to respond even more specifically to the multitude of applications and the materials to be machined, thereby further optimising the cutting behaviour. ‘We achieved the uncompromising combination of a negative indexable insert concept and cutting ease through, among other things, a specially defined arrangement of clearance areas and the coordination of macro geometries,’ explains Patrick Schwaiger, Product Manager for Milling. The result is extremely stable milling tools with optimally coordinated indexable inserts, which, thanks to sophisticated cutting geometries and innovative cutting materials, are characterised by excellent fatigue strength, ideal chip flow and precise concentricity.

Coordinated down to the last detail

Despite its negative design, a key feature of the THETAtec 25N Feed is the positive cutting geometry of the tools, which ensures easy cutting. ‘Thanks to the explicitly coordinated milling geometry, this also applies to HFC milling in full grooves,’ adds Schwaiger. Specially arranged radii across the cutting edge enable optimum absorption and distribution of the axial cutting forces. This means that considerable tooth feeds (fz) of up to 1.4 mm are possible during high-feed milling, even with a plate size of 09. Thanks to the coordinated clearance areas, it is also possible to ramp into the solid material linearly and helically without any compromises. ‘At the start of the new development, it was extremely important to us not to lose any machining options here,’ emphasises Patrick Schwaiger.

Wide variety of cutting materials for a broad range of applications

The exceptional performance of the THETAtec 25N Feed milling tool systems and their suitability for a wide range of applications are also made possible by a variety of cutting materials that are well established on the market. One highlight here is the proven Boehlerit fine grain grades in combination with high-tech HIPIMS PVD coatings.

At the start of the new launch, Boehlerit is focusing on a total of 5 cutting material grades in order to be able to machine materials from the P, M, K, H and S material groups in the best possible way.

The new high feed system is available as a shell milling cutter in diameters from 40 to 100 mm for insert size 09, as a shank milling cutter in diameters from 25 to 32 mm and as a screw-in milling cutter in diameters from 25 to 42 mm. As with the DELTAtec 90P Feed, the THETAtec 25N Feed system also features axially and radially optimised tools with different numbers of teeth and the proven uneven pitch to generate stability and reduce vibrations to a minimum. The screw-in milling cutters can also be used with solid carbide extensions up to projection lengths of 300 mm.