BCM35M and BCM40M - Unsurpassed cutting power on stainless steels.

BCM35M and BCM40M - Unsurpassed cutting power on stainless steels.

Milling stainless steels is one of the most challenging tasks in machining technology. The extreme, sometime

downright contradictory properties of this material class ensure a high level of abrasive wear, suboptimal chip

break and chemical reactions with the tool material that may lead to built-up edges and, in extreme cases, to

tool breakage.

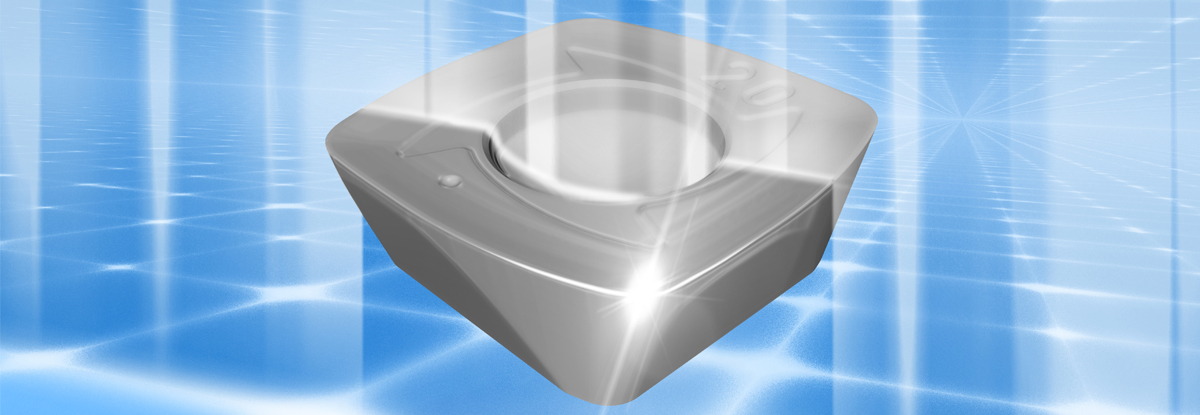

Such high requirements demand a perfectly developed tool concept. With the new grade generation BCM35M and BCM40M, Boehlerit is facing up to the challenge of milling stainless steels. As a result of intense research and development, these grades reflect all technical aspects in an optimised form.

Essentially, both milling grains consist of superfine-grain carbides with a different binder content, which is th reason why they have the best hardness/toughness ratio in the Boehlerit portfolio. In practice, this means a high level of abrasion resistance, paired with fracture toughness. The chip former and edge finish were determined after extensive simulations and trial runs, ensuring cutting power and perfect chip removal. The newly developed PVD coating is based on a multi-layer system of AlTiN and AlCrN individual layers (5-10 layer changes, depending on the thickness). The coating combines excellent abrasion resistance even at high temperatures with very good fracture toughness and temperature change resistance (delayed crack formation).

An innovative after-treatment method ensures smooth layers and reduced layer tensions, significantly reducing the adhesion of workpiece material and resulting in an excellent result when milling stainless steels.