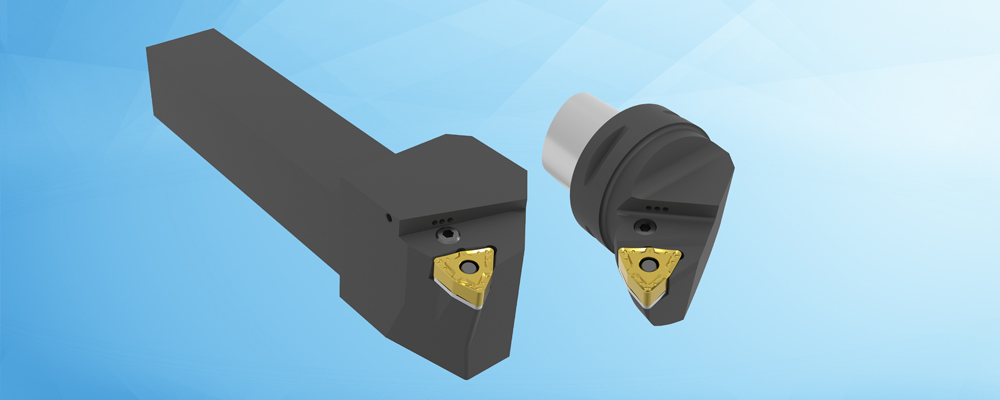

Bulltec Turn

The innovative solution for efficient and economical turning of superalloys, nickel-based alloys and stainless materials

The Bulltec Turn tooling system, equipped with an indexable insert with six cutting edges, offers numerous advantages in the application process. The specially developed micro and macro geometry has been optimised for machining superalloys, nickel-based alloys and stainless materials and ensures high performance and precision. The insert thickness of 9 mm also ensures improved stability, which means that a longer insert life can be achieved. The ability to choose between MM geometries for medium machining and RM geometries for roughing applications allows users to customise the insert to the specific requirements of their machining processes. This leads to the best possible, extremely efficient results.

The newly designed tool holders can be customised to meet specific customer requirements and the additional option of producing prototypes using 3D printing also ensures a fast and flexible response to new requirements and shorter delivery times. Overall, the new Bulltec Turn tooling system offers increased cost-effectiveness, improved machining results and efficient customisation for various applications. This makes it an innovative and powerful solution for machining technology.