Know-how from the machining of tubes

Boehlerit offers a unique range of products and complete machining solutions for the entire pipe manufacturing process in all dimensions. This begins with the machining of weld edges and extends to the external and internal deburring of weld seams and pipe end machining.

The manufacture of large-diameter pipes, such as those used in pipelines for transporting liquids such as oil or natural gas, is now carried out in highly integrated overall concepts with intelligent production lines. The production of small tubes for precision applications in the automotive industry is similarly demanding. For this reason, the production steps interlinked from coil or sheet to finished tube require maximum process reliability. This also applies, of course, to the various machining operations integrated into the process sequences. Here, exceptionally robust tool systems with long tool service lives are required in order to avoid production stoppages due to downtimes or set-up times of the expensive equipment.

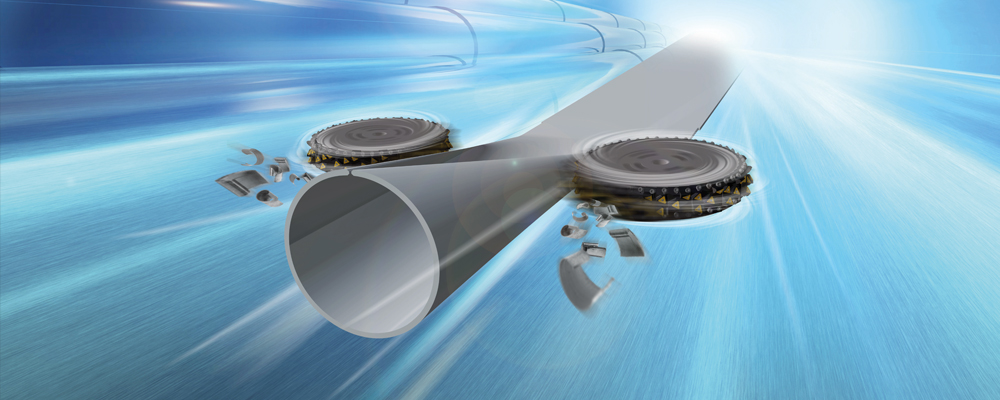

In order to cover the various machining steps, Boehlerit, as the leading tool supplier in the industry, has developed the most extensive product range on the market over the decades, including standardized solutions today. The first machining step in the process sequence is the preparatory welding edge machining. In this process, the strip or sheet edges are machined synchronously on both sides in a continuous process, with milling heads facing each other. These tools are designed and manufactured specifically for the respective systems as well as for the materials to be machined, the material thicknesses and the required edge profiles.

Modular standard components

Boehlerit offers modular profile milling heads as a particularly economical and flexible solution. They consist of a base body with exchangeable milling cassettes and indexable inserts. The cutting contour produced is determined by the shape of the cassettes. One advantage over conventional monoblock tools is that in the event of damage, only the affected cassettes need to be replaced, not the entire tool. Additional adjustment work is not required. Furthermore, by replacing the cassettes, the cutting edge profile can be changed quickly and easily if necessary, for which a completely new tool would otherwise have to be procured.

With corresponding milling cassettes and indexable inserts, Boehlerit maps all the edge profiles in demand in the industry. This means users can choose between I-profile, X-profile, Y-profile or tulip profile.

In the case of longitudinally welded tubes, the next machining operation is to deburr the weld seam from the inside and/or outside using scraping tools. Boehlerit offers the necessary clamp holders, cassettes and cutting inserts or cutting rings. These tools are also designed specifically for the application and their geometries are adapted to the diameters of the pipes. The particular challenge here is that deburring takes place very soon after welding, so the cutting inserts are usually exposed to the still very high temperatures in the weld seam. Special cutting edge geometries and carbide grades are therefore used here.

Large-diameter pipes for pipeline construction, in particular, require machining at the pipe ends to enable them to be welded together. The accuracy requirements are achieved using turning processes, for which Boehlerit supplies complete tool systems consisting of face plates, spring-loaded tool slides, cassette holders, copying rollers and various spindles for adjustment. For cassettes and indexable inserts, there is an extensive standard program from the catalog.