Boehlerit - Your partner for machining of titanium materials

The BCS10T inserts from Boehlerit for machining of titanium materials enable cutting data to be adjusted by around 25%. In practice, tool life increases of up to 40% are achieved.

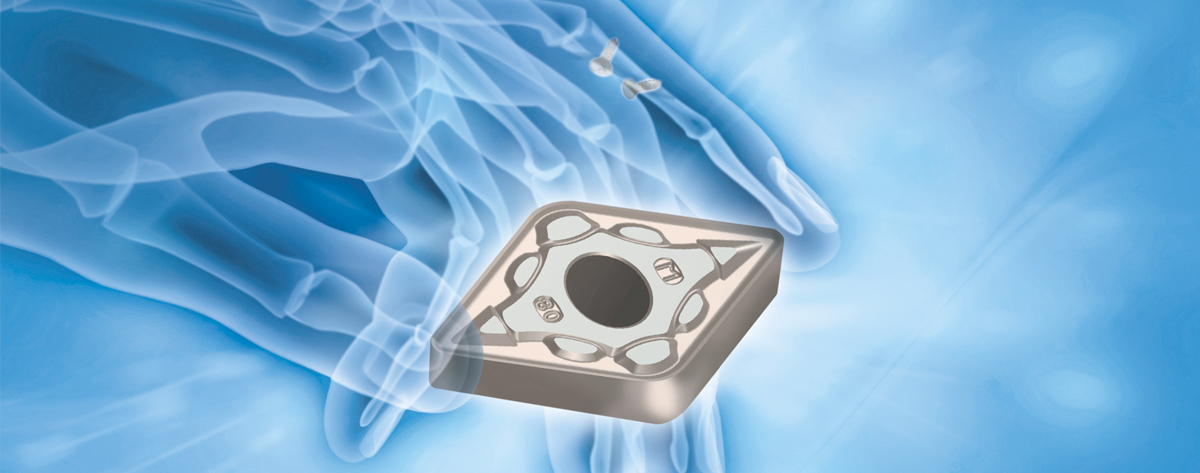

More and more high-performance materials such as Inconel, Hastelloy, Waspaloy or titanium are being used to replace traditional materials in many technical areas. These special materials are mainly used in the aerospace and automotive industries or in medical technology. However, they are considered difficult to machined and require special tools and inserts for turning and milling. Boehlerit has been successfully active in corresponding high-tech areas for many years. With the BCS10T (ISO-S10) grade, Boehlerit offers an excellent solution for turning of titanium materials. Until now, mainly uncoated K10 inserts have been used for machining of titanium materials. For the development of the BCS10T, a selected K10 fine grain substrate was also chosen as carbide. This carbide substrate is particularly temperature-stable and has a low tendency to plastic deformation. In addition, Boehlerit uses a special coating - a 3 µm thin TiB2 layer, which is deposited using the latest PVD processes, making it even more temperature and oxidation resistant and with a low tendency to stick. A factor that is essential for machining of titanium materials. Boehlerit's engineers have also developed a special chip former MT (medium titanium), which is used in the BCS10T grade. With a sharp cutting edge, this chipforming geometry ensures reliable chip breaking for medium and light roughing. For smaller ISO plates, the MT chipbreaker can be used in a feed range of 0.2 - 0.45 mm/rev. The combination of carbide, coating and chipbreaker MT in the grade BCS10T leads in practice to an increase in tool life of up to 40 %.

These groundbreaking developments are particularly suitable for use in special niches to machine unalloyed titanium grades such as Ti (ASTM1-11), α-alloys or α+β-alloys (e.g. Ti-6Al-4V) with a high degree of reliability. In addition to further innovations in the areas of carbides and coatings, the experts of Boehlerit in Kapfenberg are increasingly working on the development of new geometries for machining of special materials.