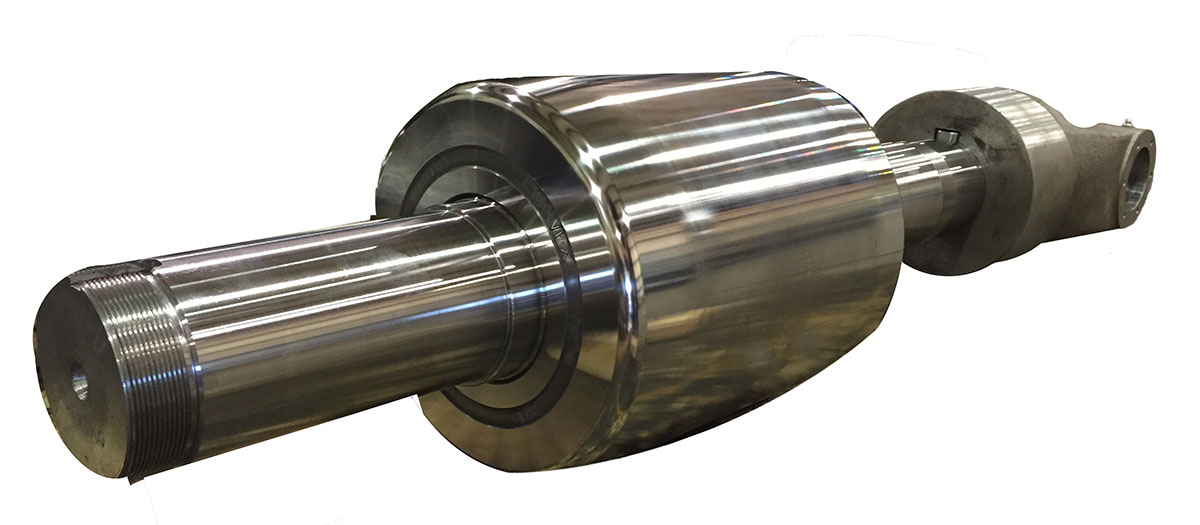

Straightener Rolls- New and Complete Reconditioning

Roll Machining Technologies and Solutions has new technology with their precision made straightener roll tooling. "RMTS uses the same proprietary Super RollTM process for manufacturing the new rolls that the customers expect from us," says company Vice President, Michael Strand who has been manufacturing these rolls for almost 30 years. This experience is critical when designing and manufacturing tools that need to have precision parabolic radii in them. This is where RMTS' hands on experience running mills far exceeds any traditional roll manufacturer.

RMTS' reconditioning process includes a full inspection of the tooling: rolls, shafts, seals, bearings, lock nuts, lock washers, and housings. Your profiles are carefully examined by our engineering team, led by Dr. Li, to determine the appropriate action to take with the tooling.

This proprietary process of straightener roll reconditioning and manufacturing has extended roll wear keeping your runs longer and saving you money. RMTS manufactures and reconditions rotary straightener rolls for tube, pipe, bar sections for Mac-Hemp, Maier, Turner, Bronx, Sutton, Taylor Wilson, 2 Roll, 3 Roll, 5 Roll, 6 Roll, and 10 Roll Burnishing.