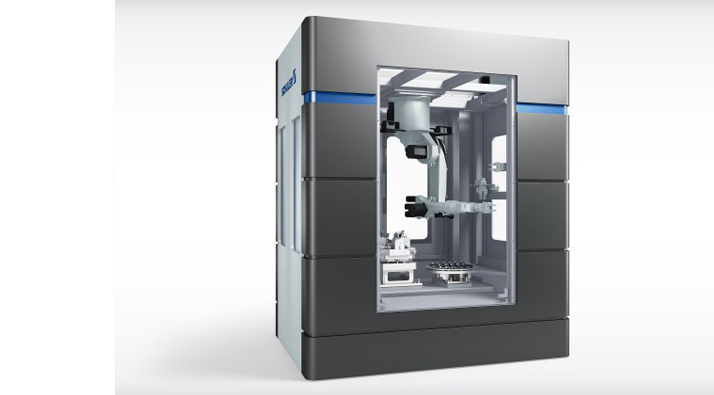

LoadMaster® Assist takes the load off system operators

Newly developed robot cell for loading systems from Schuler takes over the clamping of raw parts as well as other tasks

LoadMaster® loading systems from Schuler increase the productivity of turning and milling centers by automatically transporting parts to and from the machines. The LoadMaster Assist improves cost-effectiveness still further; the newly developed robot cell now also carries out tasks such as the clamping of raw parts in the devices or the cleaning and deburring of parts, which previously had to be performed by system operators.

LoadMaster Assist therefore takes the load off operators, who are now able to concentrate on other important tasks. The degree of automation of the machining centers is also increased to a level that not only allows lights out shifts, but also, for example, continuous operation over the weekend. The machines can remain in operation for several days without an operator having to intervene, thereby creating a greater return on investment.

"The LoadMaster Assist is the logical addition to our solutions for the automation of machine tools", says Managing Director Stephan Mergner, head of the Automation division at Schuler. The range of loading systems encompasses the LoadMaster Compact modular system, the LoadMaster Flex high rack system, and the LoadMaster Herkules for high weight classes from three to eight tons. The LoadMaster Tool links the tool magazines of processing machines.

Schuler will be presenting the LoadMaster® Assist at the AMB trade fair in Stuttgart from September 13th to 17th 2016 at Stand B92 in Hall 5.