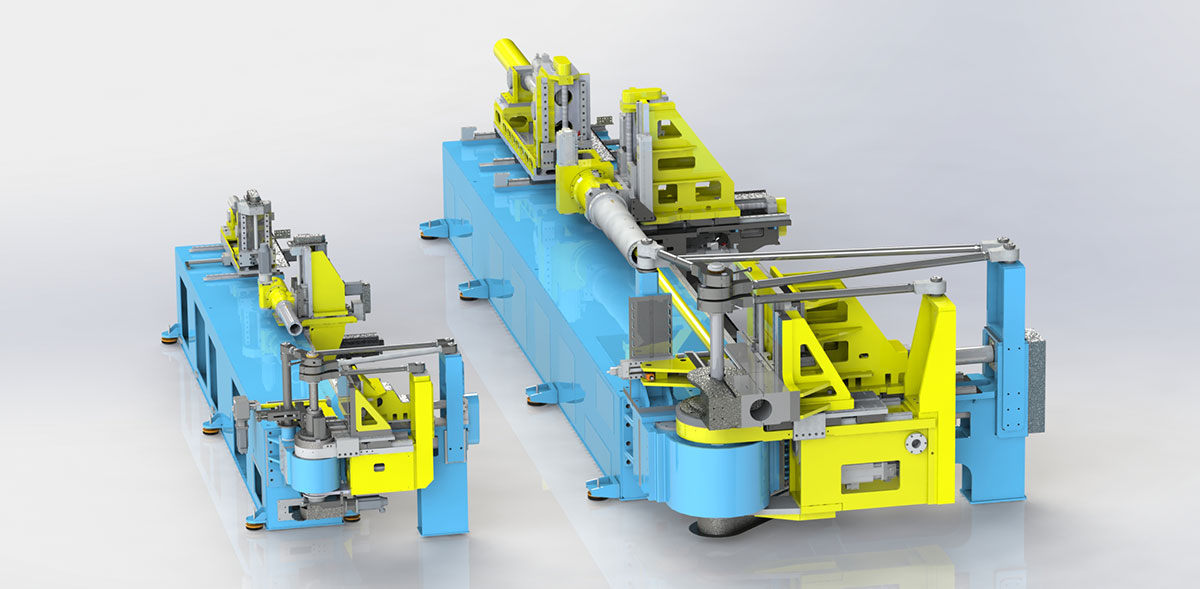

Gigantic tube and pipe bending machine on its way to the USA

The biggest fully electric multiple-radius tube bending machine featuring transport boost technology goes on a journey: The CNC 220 E TB MR has now been successfully approved at the Schwarze-Robitec production site and packed for transport to its place of use. Before the final delivery to a US-American customer from the automotive industry, Schwarze-Robitec will be presenting the tube bending machine at Fabtech in Atlanta. The gigantic machine is unique in its performance capacity. By showcasing it at booth C 10814, the traditional German company will demonstrate, how even complex tube geometries with diameters of up to eight inches can be produced swiftly, flexibly, precisely and efficiently.

Schwarze-Robitec developed the tailor-made CNC 220 E TB MR tube bending machine for one of its American customers active in the automotive industry. Short cycle times, highest speeds as well as maximum precision and flexibility were required. At Fabtech in Atlanta, the tube and pipe bending machine specialist is now presenting the result: a unique machine in terms of dimensions and capacity, with which an especially broad spectrum of tube and profile dimensions can be bent. The maximum bending capacity of the CNC 220 E TB MR amounts to a diameter of up to eight inches. The CNC 220 E TB MR processes tube lengths of up to 13 feet. A vertical height-adjustable pressure die moves to the required bending level in each individual case. This allows the requisite bending forces to be optimally gauged in order to consistently apply the optimal contact pressure to the tubes and pipes to be bent. Used in combination with individually adjustable tools, the multilevel technology integrated into the CNC 220 E TB MR allows tubes to be bent simply and precisely with very short lengths between bends.

Fast and precise production of complex tube geometries

The machine’s NxG control system also contributes to the fast cycle times offered by the High-Performance-series. By optimizing time, travel stroke and speed on all CNC axes, production times can be reduced by up to 35%. The energy-efficient CNC 220 E TB MR – like all tube and pipe bending machines produced by Schwarze-Robitec – is equipped with bend former retraction as a standard. Therefore, the bend former and swing arm can be operated separately. This enables users to produce a highly diverse range of tube geometries while easily adjusting and positioning them during the bending process. Schwarze-Robitec has already prepared the CNC 220 E TB MR for future developments in the context of Industry 4.0. For instance, the smart remote maintenance solution with numerous diagnosis functions is integrated into the gigantic machine.

Fabtech visitors looking for more information and comprehensive advice can visit Schwarze-Robitec at booth 10814 in Hall C or on the Internet at https://www.schwarze-robitec.com.