Highest quality of submarine cables ensured

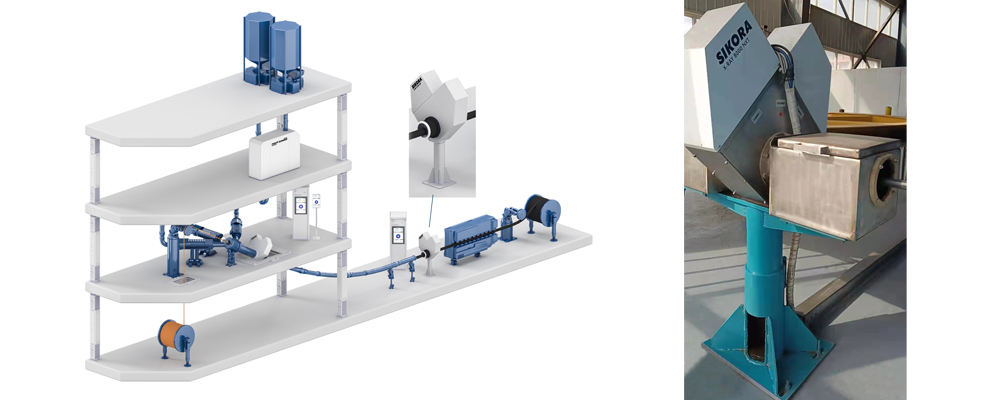

Qingdao Hanlan uses SIKORA's X-RAY 8700 NXT for final quality control at the end of the CV line The world is facing a number of challenges today, one of which is the energy transition. For this to succeed, submarine cables of the highest quality are needed, among other things, to transport electricity from offshore wind farms over greater distances to the mainland. The Chinese manufacturer Qingdao Hanlan therefore relies on SIKORA's measuring and control devices of the X-RAY 8000 device series for quality control in its CV lines. Once a submarine cable is defective, repair is very time-consuming and cost intensive. The affected area has to be located, the cable excavated and lifted, the defective area cut out and replaced by repair pieces with cable joints before the cable bundle is finally buried again on the seabed. Against this background, continuous quality assurance in the manufacturing process is essential. Therefore, many manufacturers rely on SIKORA’s X-RAY 8000 product family, which is the worldwide standard with more than 1,800 installed devices in CV lines. The systems measure inline the different cable parameters of medium, high and extra high voltage cables with up to three different layers and thus ensure that the required specifications are met. In order to offer its customers the best possible quality, the Chinese submarine cable manufacturer Qingdao Hanlan also relies on the X-RAY 8700 NXT from SIKORA. The system is used at the end of the CV line for final quality control. It precisely measures the wall thickness, diameter, eccentricity and ovality of the submarine cables. In this way, the company ensures that only defect-free cables of the highest quality are delivered. The X-RAY 8700 NXT can be used for various applications, such as cables with solid stranded conductors as well as Milliken conductors with single, double or triple layer insulation. In addition, it is also suitable for quality control of insulation material based on polypropylene.