Shorter production time and lower costs = better quality

MUELLER OPLADENs software solutions for machines and processes make customers’ production workflows more efficient. The MO-machines for the thermal cutting of 3D contours are not therefore isolated elements, but part of an integrated process chain. With CAM modules MO-machines can be linked to upstream and downstream workflows to significantly reduce production time, material costs and errors.

The software PypeServer and/or the macro-based Corobs software are the basis for the MO Compact, Watts, MO Classic and MO Heavy-Duty machine series. The AlmaRobo software is the basis for the MO Robo series.

PypeServer is a comprehensive CAD/CAM system for the purpose of modeling cutting geometries, for nesting numerous parts to be cut on a single pipe, for assigning cutting functions to one or several machines while taking into account their respective capacity, for keeping track of current working process stages at the machines and for calculating and recording cutting times and costs.

PypeServer also provides extensive reporting functions for calculation or documentation purposes. Furthermore, PypeServer provides comprehensive reporting for downstream costing and documentation purposes. PypeServer can be fully integrated in a company’s workflow as an autonomous software system for the modeling of pipes or by importing drawings from a multitude of CAD software systems.

PypeServer offers rich data in SQL views that can be pulled into Excel and other tools for reporting, and into ERP systems or other databases. PypeServer is typically run at both the machine and in offices. In offices, CAD designers and detailers import jobs, design parts, and plan work. At the machine, machine operators nest parts on pipes and cut jobs.

PypeServer modeling module

The PypeServer modeling module permits independent production of pipe cutting con-tours represented in 3D with dimension contours. To begin with, a cutting contour such as a saddle cut is selected. Then, only a few parameters need be entered into a preset mask to allow the cutting contour to develop automatically. Repetitive contours can simply be duplicated.

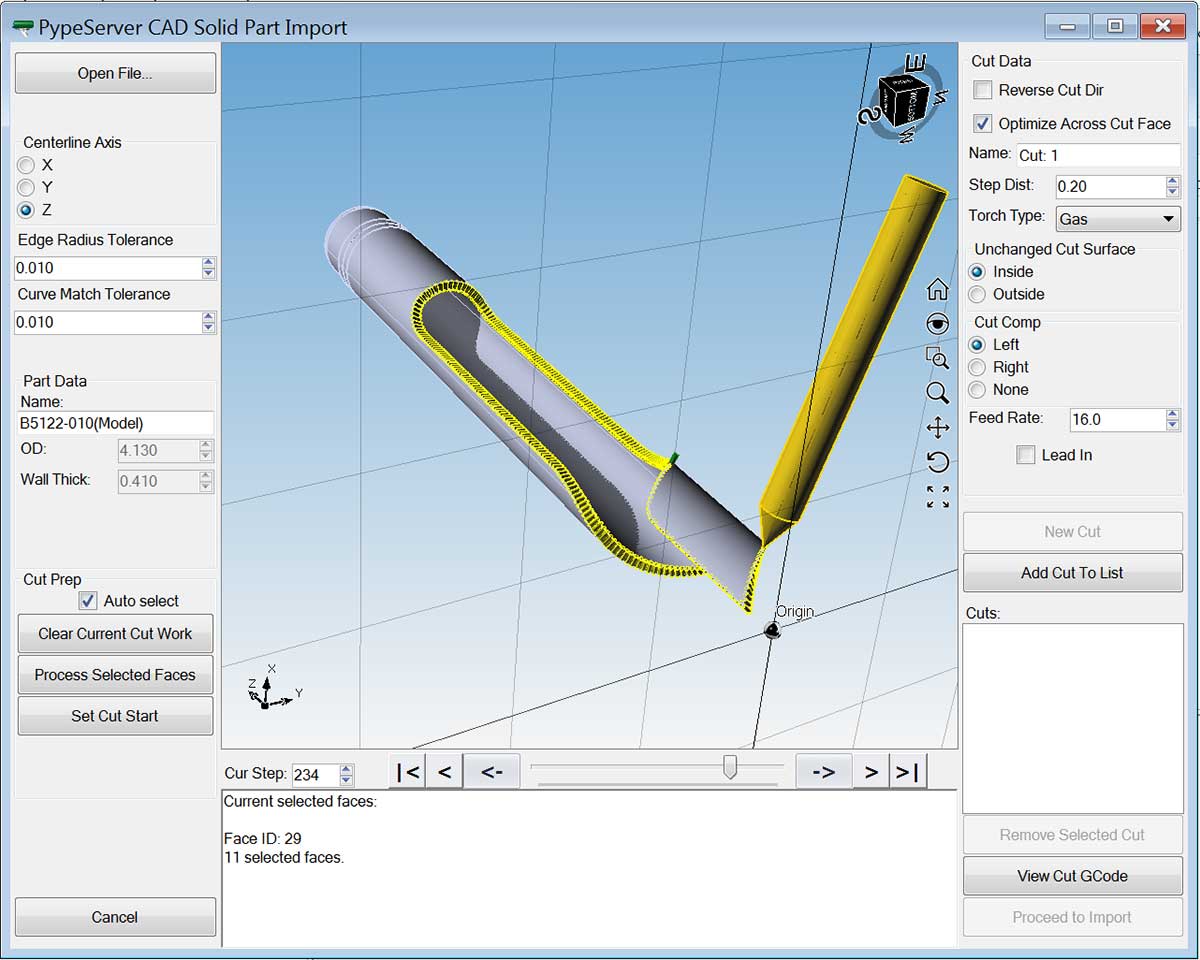

PypeServer CAD import module

PypeServer can import parts and complete design spools of most well-known software CAD systems such as Acorn, AutoDesk, Aveva, BoCAD, COMPRESS, Intergraph, Pro CAD, Pro Engineer, Ship Constructor, Solid Works or Tekla Structures. Custom importers for special CAD systems can be developed in cooperation with customers.

PypeServer nesting module

Once all the parts have either been modeled or alternatively imported, PypeServer, with a single command, automatically nests the parts on a pipe. This algorithm for such optimal nesting can save up to 10 percent in materials. The pipe segments to be cut are then shown in 3D on the monitor.

During the cutting process, both the machine operator and those using PypeServer in offices can remotely see the machines’ cutting progress. PypeServer integrates also software that can automatically print unique labels for each part.

PypeServer and SQL databases

PypeServer runs on top of SQL databases. These databases expose a rich set of data views for use in ERP, process management, inventory control, and custom reporting.

Our customers often integrate PypeServer data with their ERP system, and also with Microsoft Excel to create custom live reports for job costing, scheduling and tracking, inventory control, and post-job analyses.

Corobs macro-based programming for the MO-machine series

Besides PypeServer, the machine computer also uses our Corobs software. Through selection of a wide range of cutting macros, this allows quick preparation at the workstation of the various cuts which are then directly performed on the pipe.

In addition to this, Corobs offers various setting options with regard to cutting parameters and other sequential parameters with a view to optimizing the individual steps in each case and also depending on the properties and quality of the pipe. These functions are also provided by Corobs when PypeServer is being used since the two software systems are interconnected and adapted to each other.

AlmaRobo CAD/CAM system for the MO Robo machine series

AlmaRobo is a comprehensive CAD/CAM system running on top of Alma software. This latter ranks as the comprehensive and leading CAD/CAM software for companies in the structural steel sector. The cutting contours are generated with the aid of freely programmable software architecture. In AlmaRobo, data import from a CAD system, preferably from Tekla Structures, is followed by the automatic definition of the cutting curves and the associated creation of a cutting file. AlmaRobo then sets the start and end points for the cutting task. After this, the overall cutting process of a cutting file is simulated with the depiction of the machine and the workpiece before the start of cutting proper. The CAM tools in AlmaRobo have a design similar to those in PypeServer.