Extra-accurate measuring of extra-large pipes

A modern, automatic system to control LSAW pipes straightness will replace manual procedures, with clear and immediate benefits to the production cycle at Cimolai, Italy.

With a workforce of around 4,000, and 150,000 tons of equipment delivered annually, Cimolai is a reknown international major steel fabricator, highly specialized in structural products needed to build bridges and viaducts; industrial, civil, and military structures; and special products for off-shore projects and shipbuilding.

The new system to be installed in Cimolai’s Pipe Division Works in San Giorgio di Nogaro, will replace current manual measuring procedures of large-diameter pipes.

Operating in full automatic mode on LSAW products with ODs up to 80 in. and lengths of up to 15 m, greatly improving precision and reliability of measures using an efficient and user-friendly interface.

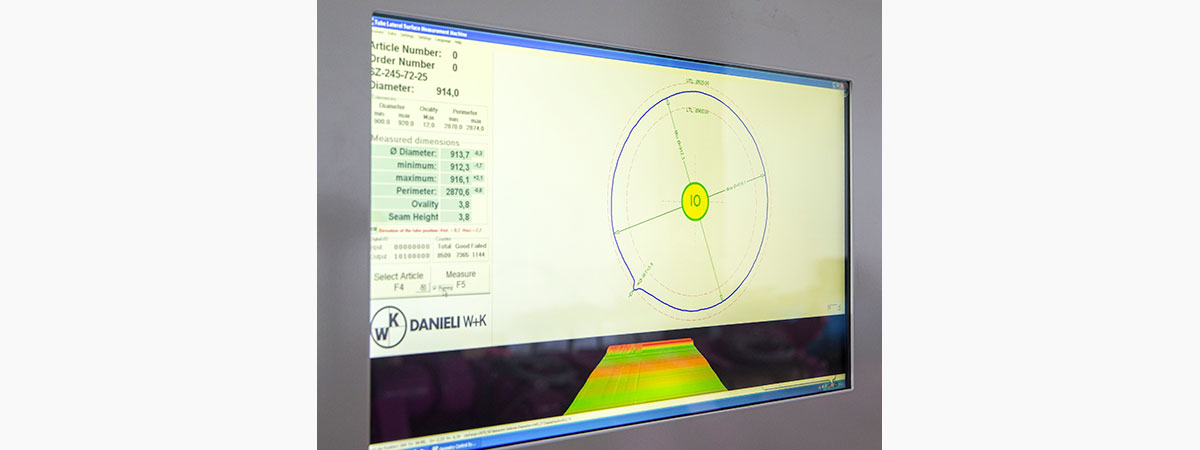

Technically, pipe straightness is calculated by a set of high-resolution cameras with specific LED lights to indicate when the product is in the static position, while an innovative software allows 3D digitalized pipe imaging; then, straightness is measured on the 3D model of the pipe.

OD dimensions are taken using high-resolution cameras that read the laser circle projected onto the external surface of the pipe.

The internal automatic calibration system substantially eliminates the requirement to feed sample pipes, therefore offering a substantial reduction in setup time.

A quick and effective measurement data exchange between the various production management systems is easily achieved through Ethernet protocols.