Weld Monitoring System for Tube and Pipe Production

Xiris Automation Inc. is pleased to announce that it will display its new Tube and Pipe Weld Monitoring System at the upcoming Tube Duesseldorf fair, stand 06-6J09, April 4-8, 2016 at Messe Duesseldorf, Germany.

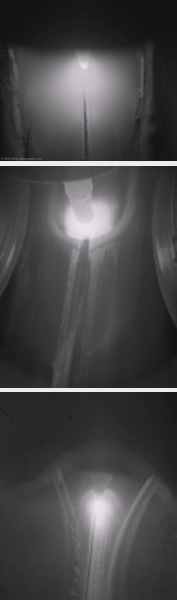

The Weld Monitoring System allows Tube & Pipe fabricators to remotely monitor their live TIG, Plasma or Laser Welding Processes. The system includes a High Dynamic Range camera that is able to simultaneously see all features of the torch tip and/or weld arc, its surrounding environment and its position relative to the Tube/Pipe weld seam. Benefits for the fabricator include increased productivity through reduced set up and adjustment time; improved health and safety conditions for the operator; and better weld quality through improved monitoring of the seam alignment and the weld process quality.

The system comes with and optics kit that allows for visibility into a small area. The result is a small enough Field of View to provide High Resolution images of the weld pool detail as the weld arc cuts the parent tube material and the material subsequently solidifies. Operators are able to clearly see if defects such as dross or porosity develop as the weld pool solidifies and monitor the condition of the weld tip, shielding gas and material fit up. For more information, please visit www.xiris.com..

Xiris Automation Inc. specializes in developing Optical systems for Quality Control for several niche industries, providing some of the world’s most dynamic manufacturers with the ability to detect, recognize, and interpret quality defects in their manufactured goods. Come by our booth for a demonstration!