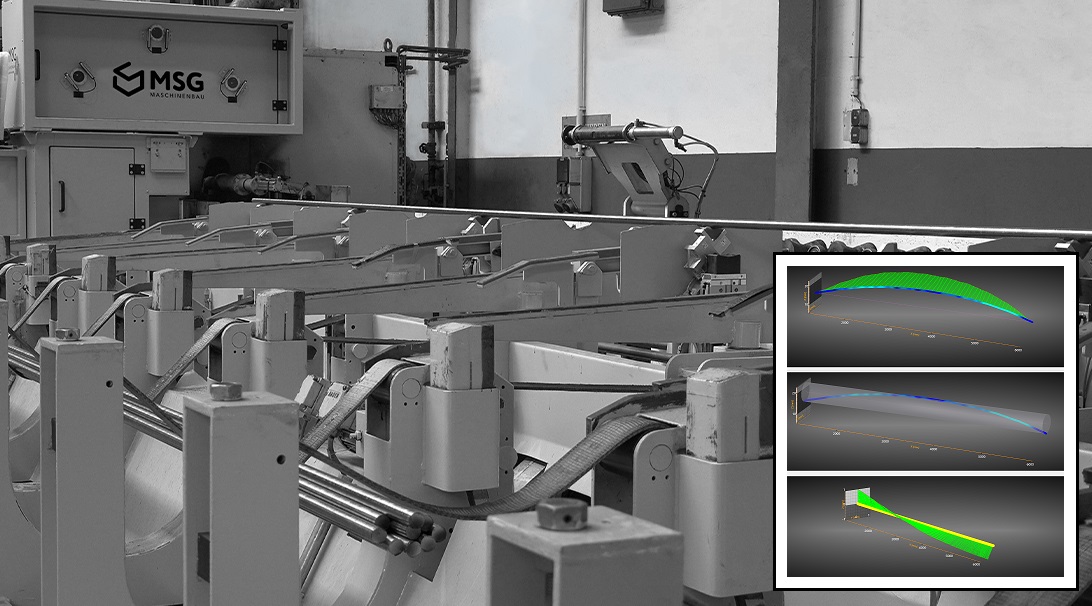

GMS-S – New Straightness measurement for round or profiled products

Future-orientated technology

Schmallenberg – Germany. The assessment of the straightness of bars, wires, tubes and/or profiles presents manufacturers with major challenges. The most obvious manufacturing process requiring an assessment of straightness is the straightening process. Whether roller-straightening or bend-straightening machines - in all cases the goal is to reduce critical irregularities below a threshold value. Even when drawing profiles or round tubes, an incorrectly set die can result in an odd profile.

Whether a product is straight or odd depends on defined threshold values. These can be specified due to finishing processes, e.g. peeling or turning, or they’re just specified through a standard document. Over decades, various methods have been developed for checking these threshold values. Whether light gap examination on highly precise measuring tables, the assessment of the oscillating movement when rolling the product over an incline, or oscillating measurement on rotating plates - all processes are either subjective or error-prone due to dynamic effects and only partially repeatable.

Objectivity and repeatability are the main features of the GMS-S (Geometry Measuring System for Straightness) developed by MSG. Regardless of the position of the workpiece in the measuring system - the shape of the measured straightness in space remains the same. "This is the only validation method that assesses the capability and accuracy of a straightness measuring system," Head of Development Matthias Kramer says.

The patented system has proven itself at VDM Metals in Altena, where the world market leader for nickel alloys and special stainless steels produces nickel bars in length of up to 12 meters. The system provides satisfactory, repeatable, and certifiable measurement results. "The mere fact that the generated measurement protocols are easily accessible, increases production reliability and drastically reduces the processing effort," Operations Manager Markus Fritz from VDM Metals says. The GMS-S offers a wide range of options, especially in the context of Industry 4.0.

If you have any questions regarding the technology or integration of this system or other products from the GMS series – do not hesitate to contact MSG Maschinenbau GmbH.