Zumbach Electronics equips Štore Steel d.o.o. Hot Rolling Mill with new Profile Measuring System

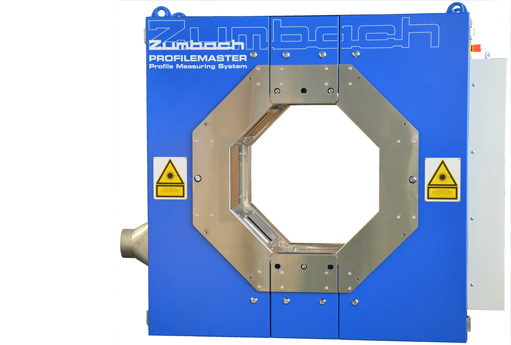

Zumbach Electronics of Switzerland won a contract from Štore Steel d.o.o. in Slovenia for a PROFILEMASTER SPS 400-S4, an accurate in-line profile measuring system, based on laser light section technique and machine vision.

The system will be integrated into a hot rolling mill, helping to increase the efficiency of the mill and to assure best product quality.

Štore Steel is producing various round and flat steel products for the forging, spring and engineering industries. As a respected steel producer, Štore Steel is modernizing their in-line measuring systems in order to gain better and faster control over their production process. A significant efficiency increase is expected by shortening start-up time and reducing down-time.

The ordered PROFILEMASTER® SPS400-S4 is equipped with state-of-the-art technology for full profile measurement and surface fault detection. The system is equipped with four high speed camera/laser modules capturing the full contour of the hot rolled profile. Scanning the product with up to 500 full contours per second, the measuring system provides continuous dimensional measurements as well as surface fault detection. The sophisticated, engineered construction and the conditioning features of the PROFILEMASTER® SPS 400-S4 ensures highly stable and reliable measurements.

The commissioning is planned before the end of 2016.

For the measurement and control in the cold finishing process, Štore Steel additionally ordered a non-contact measuring and control system from the well known Zumbach ODAC®—USYS product line.

Štore Steel ‘s choice for non-contact measuring technologies from Zumbach is justified by the good experience over many years using Zumbach instruments in their production lines, the state-of-the-art technology as well Zumbach’s after sales service.