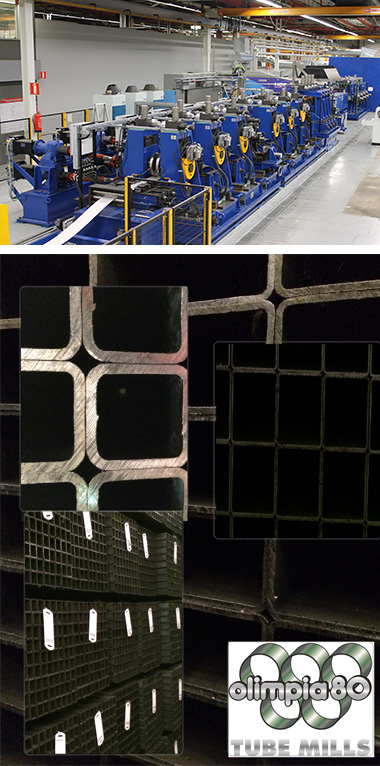

Linear Cage Forming Technology for square and rectangular sections.

According the recent new orders and the good result of our Linear Cage Forming Technology for square and rectangular sections, we decided to exhibit in TUBE Dusseldorf 2016 a complete tube mill.

The exhibited will be our model SCF 20-60, able to produce the sections from 20x20 up to 60x60 mm in a thickness range from 1 up to 4 mm at max speed 150 m/min.

In our stand (HALL 5 – STAND C21) you will see the forming, welding and sizing sections, and even the cut-off device.

This is the smallest tube mill of our range of this technology very appreciated for the precision and speed in the size change.

The customer really appreciate the total elimination of the rolls cost end even the others advantages of this technology as:

• Facility and rapidity in changing the profiles dimensions

• Very simple and easy maintenance

• Simplicity in the software utilization.

With this innovative solution, the mill makes it easy to produce both square and rectangular tubes by means of a computerized control, where all data are stored in order to produce in the best way all the tube sizes in the range. The PLC records all the utilized data and it is possible to create particular “shapes” with different angles: from the PC it is possible to see the “tube flower” of the tubes one intends to produce.

The average time for changing tube set-up dimensions is around 10 minutes. Average saving on raw material (strips) compare traditional tube mills: 5-7%. All the electrical equipment and motorizations are engineered in order to save energy, recovery power and reuse it in the line circuit.