Ukraine developed Gas-Tight Coupled Connection ‘DGT® PREMIUM’

The Ukraine developed Gas-Tight Coupled Connection ‘DGT® PREMIUM’ has been designed and manufactured by LLC ‘Dniprovskiy Pipe Works’, Ukraine (Dnipropetrovsk city) in 2015 to meet needs of gas production market and extraction technology for gas industry. Patent protected.

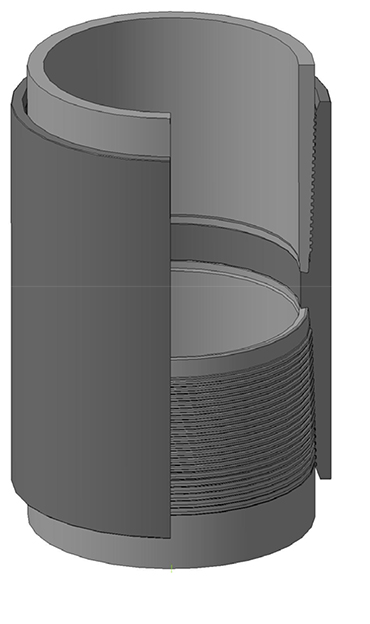

The Extra-Efficient Gas-Tight Thread Connection of ‘Premium’ Class with trapezoid-profile thread on casing and tubing pipe is destined for construction and operation in vertical and controlled directional wells for oil, gas and gas-condensate field. The ‘DGT® PREMIUM’ connection has been designed to optimize stress distribution and reduce galling during power make-up. ‘DGT® PREMIUM’ robust and durable design incorporates a metal-to-metal gas tight seal in conjunction with a reverse angle torque shoulder, in combination with Buttress thread performs 100% tensile efficient operation.

The ‘DGT® PREMIUM’ is available for Casing size range 4 1/2" thru 13 3/8" as well as for Tubing size range 2 3/8” thru 4 ½”, for various application with size option of regular and special clearance coupling.

OPTIMIZED DESIGN

The threading connection has been developed to meet ISO 13679, CAL IV technical specification. Connection design shall ensure quick and easy make-up for the most extreme environment

“METAL-TO-METAL” SEALING ELEMENT

A radial sealing system of “cone-to-cone” type with a stabilizer that has the same strength parameters with pipe body shall guarantee the most efficient tightness performance, high-rated wear-out resistance and sustained performance parameters even for critical environment under heavy pressure and high operation temperature. A “hooking” thread shall protect the connection from excessive torque application while making-up procedure and decrease circular stress in coupling in case of bending, stretching or compression of a casing string, that benefits to operate the connection in extra-depth and controlled directional wells.

A groove before sealing that is destined to protect the thread inter-space effected with excessive lubricant pressure, shall perform like a collecting area for excessive lubricants as well

PERFORMANCE EFFICIENCY UNDER COMBINED LOADING

Stress distribution is optimized with connection. Connection efficiency performance is rated to 100% while stretch loading (equal to pipe body performance).

No thread out of meshing.

STREAMLINE INNER PROFILE

Closes the inner shape of pipe, ensures smooth shifting thru the inner spacing of a string, minimizes flow turbulence, diminishes ‘wear-out sensitivity’, puts no obstacle to well-construction jobs.

EASY MAKE-UP

Designed spacing, distance from butt-end of pin and free inlet to coupling opening shall simplify preparatory and make-up connection jobs. A reliable design and performance effects for increase of assembly jobs rating.

Assembly progress may be controlled in a way of following torque readings and marks. Variation for tight-in force in sealing relative to connection size value.