2. Welding solution

3.Annealing custom solutions

Engineered solutions for the tube industry

Started more than one year ago by joining the Ajax Tocco Magnethermic Corporation group of companies, the process of consolidation and expansion of the EMMEDI brand is now ensuring the structure to steadily support presence on the tube and pipe market. EMMEDI is a high quality player in the design and manufacturing of customized induction systems and solutions for tube and pipe industry: more than 1000 units are up and running worldwide and customers can now benefit of widespread technical support and after sales services through local representatives and partners.

EMMEDI is taking advantage of the new synergies with Ajax TOCCO Magnethermic Corporation, one of the oldest and most experienced manufacturers of induction heating equipment, to offer a wide range of products designed at the highest standards.

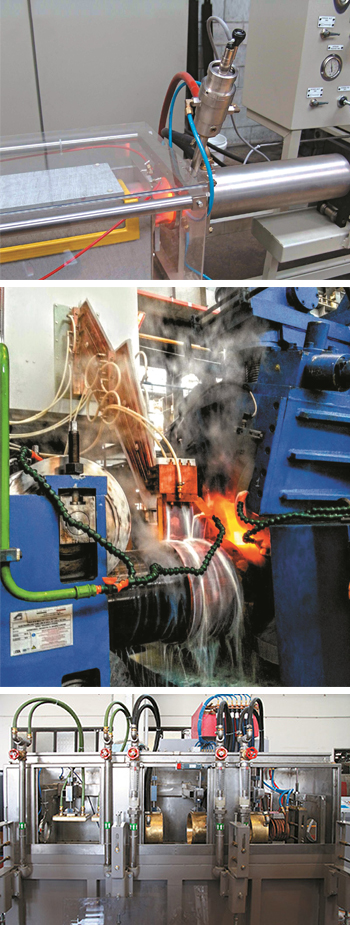

The Welding Line includes equipment renowned for high reliability, easy maintenance and simple design of inductor coils. Solid state welders have very compact cabinets and modular MOSFET based Inverters; Vacuum tube (the “Classic”) Welders, have been appreciated by the tube industry throughout the decades for the extremely robust design and strong reliability and are available with Variable output frequency range 1:1,3 or 1:2. Contact welders are suitable mainly for big pipes with high strength materials, getting to a high welding quality with a considerable energy saving. Welders can be equipped with different options. The automatic Welding table is an automatically adjustable support on 3 axis for the welding head which allows the operator an accurate inductor positioning directly from Welder Control Desk thus increasing easy and fast production set-up. EMMEDI has also developed a specific software platform, the Welding Management System. Installed in an industrial PC on the control desk, the WMS allows a real time checking of all main welding functions and the memorizing of all welding parameters and events. Working data stored can be used to repeat the best welding performances or to analyze events in the recipes database.

The EMMEDI Heat treatments Line includes various processes used for different applications.

Seam annealing units are dedicated to the normalization of the Heat Affected Zone (HAZ) required to meet API standards for Oil and Gas applications. Independent heating units with individual power control for each head grant an increased operational flexibility and the new linear coil with reduced width allows to treat pipes from 30 to 660mm OD. Temperature management is highly precise thanks to a closed loop PID system that compares the requested set point with the actual temperature read by the pyrometer. A global control of the complex system (as normally more than one unit is in line) is managed through an integrated management desk.

Full body annealing is a generic heating process used for various applications ranging from API tubes quench and tempering, Oil and Gas tubes polyethylene coating, construction tubes painting, hardening, bending and swaging. EMMEDI systems are fully customizable to meet production requirements: designed with IGBT or Mosfet Inverters, with power range from 30kW up to 3.000kW and temperature from 60 to 1200 °C according to material and application specifications. EMMEDI is able to supply turnkey solutions with mechanical loading-motorized rolls and unloading stages for off-line solutions.

The In-line bright annealing process in mainly used with stainless steel and titanium pipes for various application such as petrochemical, furniture, automotive, food and beverage. Due to a lower heating time, a partial solubilization of chromium carbides obtained with respect to the one reached with traditional furnaces thus increasing resistance to corrosion, especially in the welded zone.

The in-line system requires reduced floor space, the process is fast (no warm up time) and precise, and gas consumption is limited. The unit is provided with an automatic safety control system in case of tube bending and a Smart control desk can be supplied for the management production recipes.

The Heat treatments Line includes equipment for PET coating which is considered an

excellent process to protect tubes surface against chemical and mechanical aggression,

In-line bright annealing for refrigeration tubes to normalize the tube to work basket-to-basket, and in-line double wall copper brazing mainly applied in the automotive industry for breaking system circuits and fuelling distribution.

Throughout the years EMMEDI has increased competences and skills in the design and manufacture of customized solutions and is able to answer the most demanding requirements thanks to SAET metallurgic laboratory and expertise in mechanical handling.

Along with providing each customer personal service, a proven process and reliable equipment, EMMEDI customers can benefit from the resources of a global corporation providing worldwide assistance through its network of regional sales and service engineers. Experienced service teams are strategically placed for quick response to customers wherever they are located.

Thanks to the strong backing from the corporate Park Ohio Holdings and in an effort to become more of a universal resource to customers, the group gathers companies and products that span far beyond just the induction equipment: heat treatment applications, end-finishing and coupling threading equipment, custom tube and pipe bending and processing machinery. A combination of brands such as Ajax Tocco Magnethermic, Pillar, PMC-Colinet and Pines will bring value to customers’ organization and businesses and provide great opportunities to the tube and pipe industry.

EMMEDI will be present to the most important trade shows in 2016 to present its range of products and services.