High Performance Coolant for the Pipe Threading Process

Quaker Chemical gains efficiencies on tooling costs and solves coating incompatibilities with QUAKERCOOL® 750 TP

CONSHOHOCKEN, PA (February 24, 2015) – For many pipe manufacturers, annual threading tool costs can be ten times or more than the annual costs of the coolant. Quaker Chemical Corporation (NYSE: KWR), the only “front to back” chemical specialty supplier to the Tube and Pipe industry, addressed the issue with QUAKERCOOL® 750 TP. This metalworking coolant fluid is a high performance mineral oil-free microemulsion. Benefits include exceptional lubrication, short term corrosion protection, clean rinsing, and a wide water quality tolerance. It effectively resists microbiological growth and does not contain chlorinated compounds, formaldehyde release agents, boron, monoethanolamine, nor secondary amines.

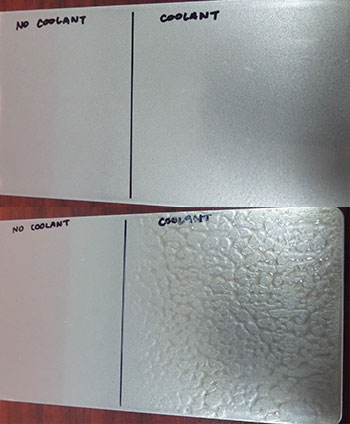

A major OCTG pipe producer desired to lower their operating costs while at the same time improving their threading quality and cutting insert wear. Quaker worked closely with the customer with the target to gain efficiencies on the tooling costs, which are often the most expensive part of the threading operation. After incorporating QUAKERCOOL® 750 TP into the threading process, the results were:

- Up to 30% increased tool insert life

- Decreased downtime due to longer tool use

- Significant reduction in cost per joint, saving the customer hundreds of thousands of dollars