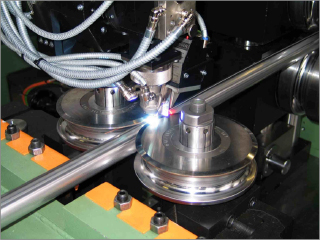

Next level of stainless steel tube production

A renowned South East Asian producer of high class stainless steel tube products for the automotive industry placed recently an order about a tube mill with SEUTHE

Challenging thin-walled stainless steel tubes up to a tube diameter of 60.0 mm and a min. wall thickness of 0.5 mm will be produced on this specially developed laser mill generation. High precision tube production is the key target. Individual drives in the tube forming and sizing section are supporting challenging tube dimensions in combination with perfect tube surface quality. The high-class stainless steel tubes to be produced on the SEUTHE mill will be seam grinded, laminated, non-destructive tested and chip less cut, even in shortest tube lengths. The tubes can pass an inline heat treatment to homogenize the microstructure and bright anneal the tube surface. Further tube manipulation processes are integrated in the tube finishing section. What makes this tube mill unique is the solid engineering “Made in Germany”. Consequently as a result the customer benefits from reproducible mill settings and a fine-tuned mill control system to reach high productivity at a consistent product quality.

SEUTHE, a member of the ASMAG group, is a renowned premium machine supplier to the international tube and pipe industry.

Next level of stainless steel tube mill can be seen in our showroom – please contact us.

SEUTHE GmbH

Deilinghofer Str. 11

58675 Hemer, Germany

Tel.: +49 2372 506 0

sales@seuthe.com

www.seuthe.com