Page 41 - ITATUBE Journal 1 2020

P. 41

Press Releases

vertical transport carriage. A ver- tically adjustable pressure die moves to the individual levels in sync with the tube. This means that the contact pressure can be optimally gauged, while tool costs and tool changing times are reduced.

Furthermore, additional features of the machine help to ensure an even faster production process. For example, for each bending sequence the intelligent NxG control system assesses the inter- action between all axes, operates them simultaneously and prepares the next sequences. This reduces production time by 20 to 40 percent depending on the compo- nent and the desired tube geom- etry. In addition, faster refitting times are ensured thanks to the Quick-Tool-Unlock system in com- bination with a rapid clamping system for the bend former. The tension bars can thus be opened and closed with ease for tool changing, whilst no bolts are required to fasten the bend former to the turntable. This helps to increase repeatability and process security.

Schwarze-Robitec has perfected this machine through numer- ous refinements, such as a freely stored bend former. Fabtech trade fair visitors in Chicago were able to witness a highly efficient tube bending process up close.

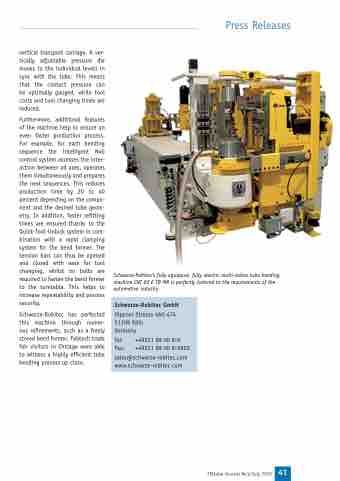

Schwarze-Robitec’s fully equipped, fully electric multi-radius tube bending machine CNC 80 E TB MR is perfectly tailored to the requirements of the automotive industry.

Schwarze-Robitec GmbH

Olpener Strasse 460-474 51109 Köln

Germany

Tel: +49221 89 00 8-0 Fax: +49221 89 00 8-9920

sales@schwarze-robitec.com www.schwarze-robitec.com

ITAtube Journal No1/July 2020

41