Market Overview

Have a look ...World Tube & Pipe Market: Factors influencing the current situation

Dr. Gunther Voswinckel – Update as per December 2022

Welcome to ITA’s and VOSCO´s regular presentation of the main worldwide economic factors influencing the tube and pipe industry.

In many regions of the world, the corona pandemic seems to be under control. Nevertheless, we can understand its impact on the supply of goods, especially in China, where some important cities are again affected by corona lock down.

The Ukraine war represented another striking turning point this year. Russia, as one of the main suppliers of fossil energy commodities, gas and oil, was hit with sanctions as a result of its invasion of Ukraine. Europe in particular, which is highly dependent on Russian gas and oil supplies, is being hit hard by the resulting skyrocketing energy prices. The consequences of the cost increases are unevenly distributed across the world. Regions such as the USA, India, Turkey and China are benefiting from lower energy costs. In addition, massively rising inflation and its countermeasures threaten our industry and present it with unexpected challenges that are difficult to calculate. As always in such disruptive times, we see crisis winners who maximise their profits - but also crisis losers who have to fear for their existence. Due to the dynamics of these developments, it is usually very difficult for the crisis losers to react appropriately. As a result, some regions are looking for suitable political countermeasures to compensate for their cost disadvantages.

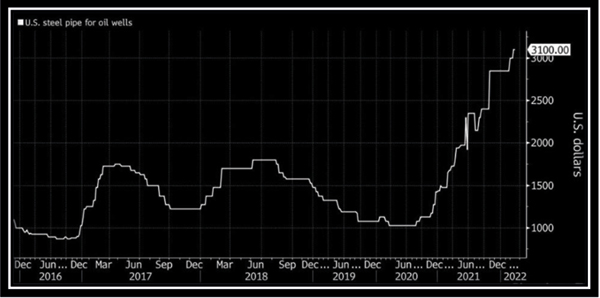

Whereas previously only quality, delivery time and costs were decisive, geopolitical and logistical risk considerations as well as current and future energy costs are now increasingly taking centre stage. All sources of supply are being critically scrutinised and one can only hope and warn that international trade will not suffer too much as a result. In particular, the regional differences in energy prices will have an impact on the current landscape of the energy-intensive steel industry. For many years, Europe benefited from relatively cheap pipeline gas from Russia. As this will no longer be available for some time, Europe will have to compensate for these supplies with much more expensive other sources. As a result, energy prices will remain at a much higher level unless Europe produces more gas from its own territories despite all political opposition. On the other hand, regions like the US, China and India will continue to expand their energy-intensive industries because energy costs are much lower there. More than 70 % of total world pipe production, i.e. about 110 million tonnes, is welded pipe. Welded tubes are highly dependent on hot-rolled coil prices and, to a lesser extent, on plate prices. Average prices for hot-rolled coils jumped from September 2020, from around USD 450, to a peak of USD 2,000 in September 2021. Prices then fell throughout 2022 to around USD 620. This price rally posed major challenges to our pipe industry. Although tube prices also peaked, the price increase was higher for hot-rolled coils than for welded tubes. Most forecasts now predict that prices for hot-rolled coils will settle down and increase by a maximum of another 80 UDS by 2023. But demand for pipes is also calming down with similar effects on prices. Prices for commodity pipes in Europe are currently around 830 USD/tonne, resulting in a value added of only 210 USD/tonne at most. Only the US market is still quite demanding at a high price level. OCTG pipes, which have a much higher material requirement, are traded at prices of about 3,000 to 4,000 USD/tonne in the USA.

Further opportunities are expected as new pipeline networks need to be built to follow oil and gas logistics as the war in Russia has made some of the existing pipeline system obsolete. Transporting oil and gas by pipeline is by far cheaper and more environmentally friendly than transporting LNG by ship.

Logistics costs have only recently fallen to normal levels, reducing supply bottlenecks for the steel industry.

Another challenge arises if policies to prevent climate change, such as the additional carbon costs agreed by the European Union, are not introduced in a balanced way. These impacts may also cause industries that consume a lot of energy to move to regions with lower costs. The confidence to compete on the world market with these additional costs in the future is fading for some pipe manufacturers. Pipe mill infrastructure in terms of pipe mills and finishing lines as well as digitalisation and applied quality assurance systems also play an important role. Increasing importance is attached to agile management strategies in terms of customer benefits, process and product quality improvement as well as purchasing processes using "Industry 4.0" measures.

With a view to the return to normality, it can be seen that both plant manufacturers and technology suppliers are increasingly finding interesting business opportunities in this new market segment. Some technology suppliers have already reacted to this and expanded their product portfolio to include digital solutions.

The International Tube Association has organised several well-attended webinars in 2020, 2021 and 2022 to maintain the exchange within our industry. This year, in May 2022, "Engineered Tubes for the Automotive Industry" and in November 2022, along with the Tube India 2022 exhibition, a hybrid congress titled "Emerging Technology and Innovations in Pipe & Tube Industry" was successfully organised by the ITA Indian Chapter. It was great to meet both tube manufacturers and suppliers to the tube industry at our world's largest tube trade fair 'Tube Düsseldorf 2022' and the regional trade fair 'Tube India 2022' in Mumbai. The positive response to these events is a sign of the impressive optimism in our tube industry.

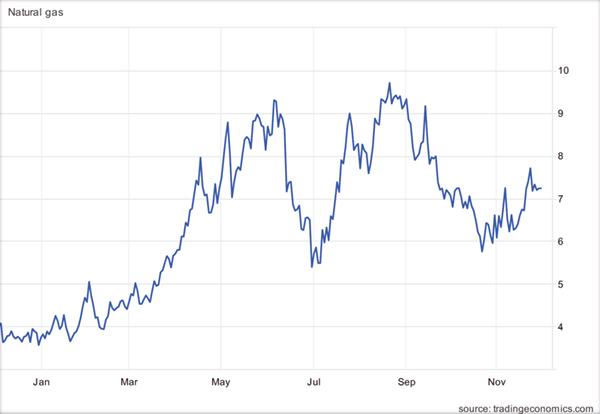

The high cost of energy is a major challenge for our industry. The prices for gas (Figure 1) and electrical energy (Figure 2) are causing dark clouds over our steel and tube industry.

The price of gas peaked at around USD 9.8 at the end of August 2022, i.e. about 250% higher than at the beginning of 2022. Since November 2022 (USD 6), the price of natural gas has risen again to around USD 7.5. Gas can only be transported over long distances by ships as LNG (liquefied natural gas), which requires expensive treatment compared to natural gas transported by pipeline. For the liquefaction around 10-25 % of the calorific value of the natural gas is consumed. Therefore, regions like North America benefit from much lower gas costs as they have their own gas resources that can be used directly as natural gas. Europe has benefited for many years from cheap Russian pipeline gas, but now and in the future Europe will have to rely on much more expensive LNG gas, which means a significant cost disadvantage of about 20% for energy-intensive industries such as the steel and pipe industries. It remains a major political challenge to secure that this cost disadvantage will be overcome to ensure European energy intensive industry to be again cost wise at eye level with the industry in other regions. To explore more of the own regional European gas resources may be a valid option hereto. Electrical energy, the other major source of energy for the steel and tube industry, has also seen massive price increases, peaking in Europe in August 2022 (€500) and increasing tenfold compared to January 2020 (€50)!

Since 22 August, the price of electrical energy has dropped to €150, but still remains three times higher than in January 2020 (about €50). Compared to Europe, electrical energy prices in the US are far lower, only about 30% of European prices. This price difference is another disadvantage for the energy-intensive European steel and pipe industry.

Pipe manufacturers buy hot-rolled coils, round billets or plates as input material for their production lines. More than 70 % of the total world pipe production, i.e. about 110 million tonnes/year, are welded pipes. Welded tube producers are highly dependent on hot rolled coil prices and to a lesser extent on plate prices. Average prices for hot-rolled coils started to spike in September 2020 (around USD 450) and peaked at USD 2,000 in September 2021. Since then, prices have fallen to around 620 USD throughout 2022. However, a further maximum price increase of 80 USD/tonne is expected again for 2023.

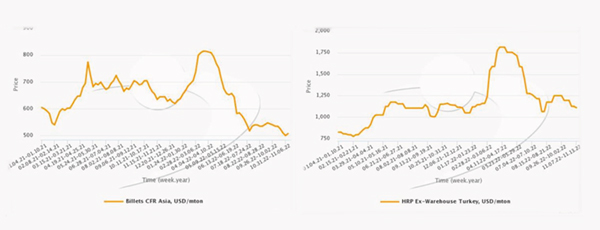

Steel plate prices rose to an average price of around USD 1,800/tonne in the first quarter of 2022 and are now trading at an average of around USD 1,000/tonne in November 2022 (Figure 3). Billet prices, used for seamless tubes have not risen nearly as much as hot rolled coil prices, yet these prices have also cooled from average 810 USD/tons to an average of around 500 USD/tonne (Figure 3). This price rally has posed major challenges for our tube industry. Although pipe prices also reached all-time highs, the price increase was higher for hot-rolled coils in particular than for welded pipes, leading to an erosion of pipe manufacturers' margins in many regions of the world (Figure 4).

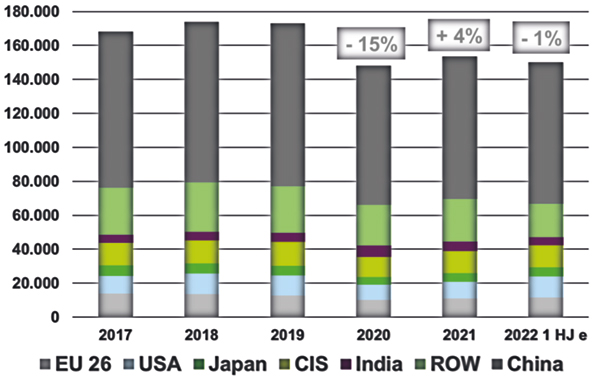

If we look at the European pipe market as an example, so far about 20% of pipe imports have been served by Russia and the Ukraine. In the case of seamless pipes, the import share from Russia and Ukraine was even as high as 40%. These volumes need to be supplied by other tube and pipe producers. Russian shipments in 2022 will decrease by 34% on-year to 1.06 million tonnes, the RBC newspaper reports, citing a presentation from fund director Alexander Semenchishin. Domestic consumption in Russia is seen decreasing by 2% on-year in 2022 to 9.12 Mio. tons. As a result, pipe production will fall by 5.5% to 10.04 Mio. tons. Many regions of the world such as Europe and North America need to compensate their pipe and tube imports from Russia and Ukraine. As a result of the increased demand and the lower supply of pipes, pipe prices have risen by more than 50% compared to the previous year 2021 (Figure 4) Until the beginning of October, pipe prices were still holding at high levels, but in November fears are being voiced from many regions that demand for pipes is weakening, which has an immediate impact on prices. Only the US is still reporting a sustained high for pipes. The expected decline in pipe demand and its negative impact on prices seems to be slower than the decline in prices for the input materials hot-rolled coils, plates and round billets. This would allow some pipe producers to compensate for some of the margin losses they suffered when input material prices exploded. The world tube and pipe production after a slight recovery in 2021 of 5%, was maintaining its world production level at about 150 Mio. tons in 2022.

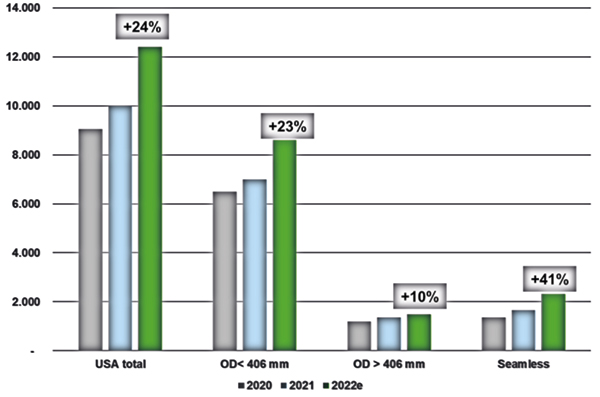

Anyhow substantial regional differences are reported. Whereas the rest of the world (-22%) and India (-14%) suffer from less production of tube and pipes, the USA, driven by a strong OCTG and construction market report major growth in production (Figure 6).

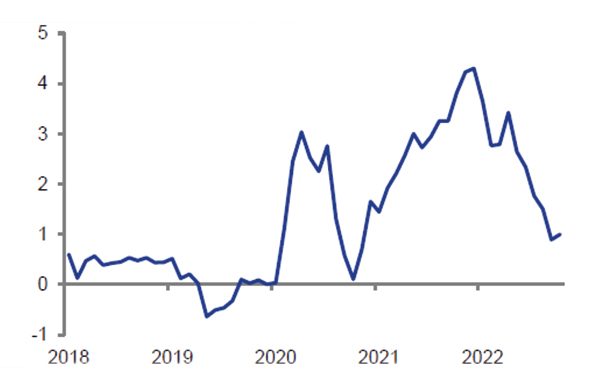

Due to the coronal pandemic, supply chains and freight costs were severely affected. This situation has now improved. The supply chain pressure index has improved significantly, from index values of 4 at the beginning of 2022, the index has returned to normal values of around 1 this November (Figure 7).

Freight rates have also returned to near normal rates (Figure 8). Global rates of USD 10,000 at the beginning of 2022 have now fallen back to around USD 3,000. Freight rates from China to Europe of 14,000 USD at the beginning of 2022 have settled down to freight rates of around 3,500 USD in October 2022. These are good news for the industry and contributes to the recovery of international trade.

Another good sign for our industry can be seen in the prognosis, that Inflation has passed its maximum and shall further decline until 2024. The affords of the central banks, especially these of the US FED, has stopped the galloping inflation and reversed the trend (Figure 9). Anyhow we hope that Morgan Stanley does not see the situation too optimistic.

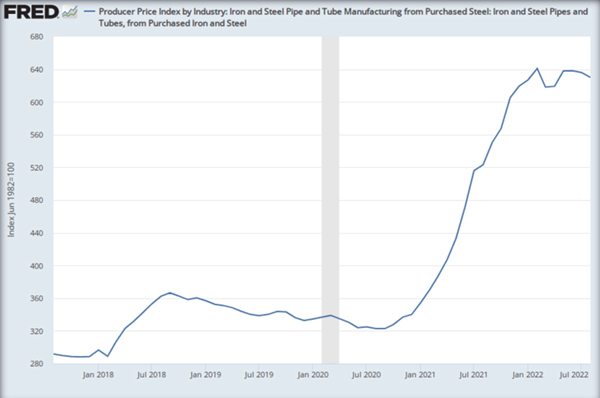

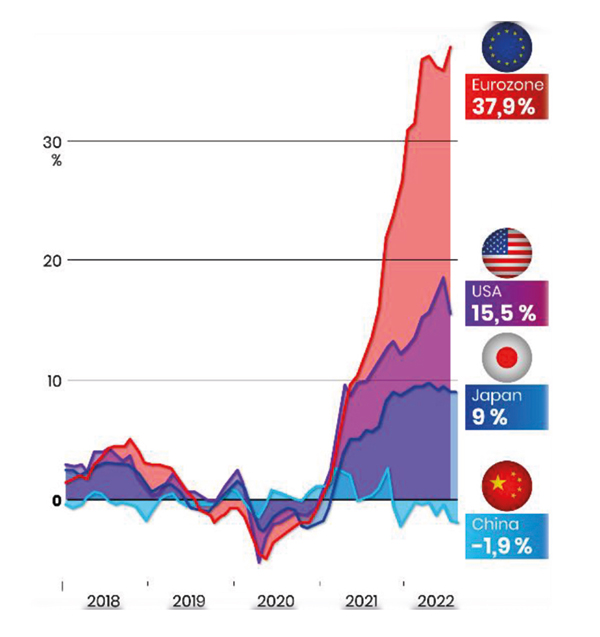

In addition to the inflation rate, the producer price index is an important parameter, as it reflects the costs of the manufacturing industry. As Figure 10 shows, these costs vary greatly from region to region. Europe brings up the rear here due to the sharp rise in energy costs. As already explained, the USA has here compared to Europe a significant advantage of more than 22% due to cheap local energy. China's cost situation is particularly advantageous here but is certainly shaped by weak demand due to the corona lockdowns.

As already stated, one major driver of the tube and pipe market is the OCTG market representing about 51% of the world tube and pipe production. After Corona the industrial production has picked up and led to a sharp increase in energy consumption since 2021, so that supply has hardly been able to meet demand (Figure 11). Secondly, the geopolitical sanctions created a massive contraction of Russian production causing speculative price increases (Figure 12). It is anticipated that the Russian Oil production may be reduced by up to 25%.

The corona lockdown in Shanghai at the end of March 22 briefly eased the situation on the price front, as demand for energy fell noticeably as a result (Figure 13). According to Platts estimates, China’s April demand plummeted to 13.35 million Bbl/d, down 11.5% year-on-year, though recovering transportation demand may push May figures back above 14 million Bbl/d. At the peak of lockdown mandates, gasoline and diesel demand in coastal regions dropped by as much as 40%, with a grand total of 45 cities with some form of movement restrictions.

Since July 22 (120 USD/Bbl) the prices for oil went down until early October 22 (77 USD/Bbl). The oil and gas producing countries reduced the supply volumes to stabilize the energy prices leading to a price corridor between 80 to 93 USD/Bbl (Figure 11). The energy industry is booming, Aramco, the world's largest producer of fossil fuels, has become the world's most valuable company this first quarter 2022. Currently, there is no evidence that oil and gas producers are increasing supply to capture market prices. The USA anyhow, to soften the inflation, significantly increases the number of rigs from 531 in May 2021 to about 800 end of November 2022 (Figure 14).

Of these 784 rigs, 627 are dedicated for the extraction of oil and 155 for gas. The growth pattern has slightly calmed down, anyhow demand stays on high level. Efforts to reduce dependence on fossil fuels can hardly be successful in the short term and can only contribute to decoupling in the medium term. For our pipe industry, however, this means that high energy prices must be expected in the future as well. Luckily these analysts, who were anticipating another surge towards the USD130-140 per barrel range this summer 2022 were wrong, but prices around 80-90 USD are most probable. The investments to secure the energy supply will keep the demand and prices for tube products high (Figure 15).

In addition to exploration activities, the need to build new pipeline routes has also increased since the ban on Russian pipelines to Europe. In the wake of the attacks on the Northstream pipelines, which released very large quantities of methane as an environmental desaster, it can be expected that the standards for pipelines will become even more demanding. This development offers the manufacturers of large-diameter pipes > 406 mm OD opportunities for interesting business. The global construction market with about 5% of the global tube market presents another opportunity for pipe manufacturers with growth potential. A recent study published by Global Construction Perspective and Oxford Economics, entitled "Global Construction 2030", forecasts an 85% growth in global construction output to 15.5 trillion by 2030, with three countries, China, USA and India, leading the way and accounting for 57% of global growth alone. Europe, on the other hand, will reduce its pace of investment. There is room for additional production capacity for structural tubes, especially in India, to follow the market trend. The tube industry needs to further promote the benefits of tube applications and showcase the architectural perspectives (Figure 16). Tubular profiles are an ideal choice when visible structures are desired due to their varied shapes and closed cross-sections combined with smooth sides. Best mechanical properties and the possibility to bridge large spans are further highlights of tube profiles. The automotive market representing about 15% of the global tube market is a quite steady and reliable market. After the set back of the world car production in2020, and the supply chain challenges in 2021, the market will continue to grow at a rate of 2 %/year (Figure 17) with many interesting tube and pipe applications. The production level in 2020, which fell due to the Corona crisis, could only be increased slightly to around 77.2 million light vehicles worldwide in 2021 due to various challenges in the supply chain. According to IHS, the recovery process will take longer in the volume markets of Europe and North America. Future growth will take place primarily in Asia, especially in China. However, China could increasingly become a sales problem for the western automotive industry due to the American decoupling tendencies. However, the tendency to further reduce the weight of vehicles supports the trend towards the use of tubular products. The greatest potential for the use of tubular products (Figure 18) is seen in vehicle frames, followed by chassis and powertrains. Tube manufacturers need to enter new vehicle series with larger volumes to further expand their presence in the light vehicle industry.

The mechanical engineering market segment, which accounts for around 9% of world pipe production, has developed well in line with global GDP in recent years (Figure 19). During the financial- and corona crisis, the market was characterised by higher volatility with sharper declines and quick recoveries. In 2022, the current further recovery is slowed down by geopolitical circumstances. Asia, and China in particular, is the largest market for machinery purchases. Here, therefore, the decoupling intentions of the USA must be observed since these could become a game changer for the worldwide mechanical engineering industry. The USA and Europe continue to be significant sales regions as well. It remains noteworthy that the Chinese industry has taken the global lead in machinery sales since the Corona crisis. This market segment certainly has the greatest variety of tube products. Cylinder-, ball bearing- and turned part tubes, to name just a few prominent representatives of this market segment, certainly show good prospects for tube producers.

Most pipe and steel producers were able to report strongly improved economic figures for Q1 and Q2 in 2022 in the wake of the price increases. However, for European pipe producers, the additional CO¬¬2 costs agreed to be imposed by the European Community represent a major challenge. Confidence in being able to compete on the world market in the future with these additional costs is dwindling among some tube producers.

In general, there is enough production capacity to serve even the increased demand for tubes and pipes for all market segments. Raw material prices for the steel as well as the tube and pipe industry would seem to have peaked by the end of 2021.

Energy costs, however, remain high and climb even further since market interventions (e.g. OPEC plus) and warlike actions call free world trade into question. Further challenge may be imposed, if political measures to prevent climate change are not introduced in a balanced way, with possible consequences being the migration of high energy consuming industries to lower-cost regions. Nonetheless, if the balance of supply and demand within the tubes and pipes industry can be restored, price volatility can be expected to calm down. How long will it take, to realize the inflation target of 2% again? Tube plant infrastructure with respect to tube mills and finishing lines as well as applied quality assurance systems also plays a significant role. Tube and pipe producers who have used the corona pandemic to improve their productivity, flexibility and customer service, like introducing “Industry 4.0” measures, will benefit from such measures.

With an eye to the return to something like normal, it should be noted that plant builders and technology suppliers alike may find interesting business opportunities in this new market segment. Some technology suppliers have already reacted and enhanced their product portfolio with the addition of digital solutions.

It is good to realize, that besides the virtual exchange in our industry, such as the webinars organized by the International Tube Association (ITA) now again hybrid or even personal events for industrial exchange take place. The recent conference alongside Tube India 2022 this November under the headline ” Emerging Technology and Innovations in Pipe Tube Industry” was an excellent example hereto. It was great to meet tube producers as well as suppliers to the tube and pipe industry at our world largest tube and pipe show “Tube Düsseldorf 2022” and the regional show “Tube India 2022” in Mumbai.

Dr. Gunther Voswinckel

In many regions of the world, the corona pandemic seems to be under control. Nevertheless, we can understand its impact on the supply of goods, especially in China, where some important cities are again affected by corona lock down.

The Ukraine war represented another striking turning point this year. Russia, as one of the main suppliers of fossil energy commodities, gas and oil, was hit with sanctions as a result of its invasion of Ukraine. Europe in particular, which is highly dependent on Russian gas and oil supplies, is being hit hard by the resulting skyrocketing energy prices. The consequences of the cost increases are unevenly distributed across the world. Regions such as the USA, India, Turkey and China are benefiting from lower energy costs. In addition, massively rising inflation and its countermeasures threaten our industry and present it with unexpected challenges that are difficult to calculate. As always in such disruptive times, we see crisis winners who maximise their profits - but also crisis losers who have to fear for their existence. Due to the dynamics of these developments, it is usually very difficult for the crisis losers to react appropriately. As a result, some regions are looking for suitable political countermeasures to compensate for their cost disadvantages.

Whereas previously only quality, delivery time and costs were decisive, geopolitical and logistical risk considerations as well as current and future energy costs are now increasingly taking centre stage. All sources of supply are being critically scrutinised and one can only hope and warn that international trade will not suffer too much as a result. In particular, the regional differences in energy prices will have an impact on the current landscape of the energy-intensive steel industry. For many years, Europe benefited from relatively cheap pipeline gas from Russia. As this will no longer be available for some time, Europe will have to compensate for these supplies with much more expensive other sources. As a result, energy prices will remain at a much higher level unless Europe produces more gas from its own territories despite all political opposition. On the other hand, regions like the US, China and India will continue to expand their energy-intensive industries because energy costs are much lower there. More than 70 % of total world pipe production, i.e. about 110 million tonnes, is welded pipe. Welded tubes are highly dependent on hot-rolled coil prices and, to a lesser extent, on plate prices. Average prices for hot-rolled coils jumped from September 2020, from around USD 450, to a peak of USD 2,000 in September 2021. Prices then fell throughout 2022 to around USD 620. This price rally posed major challenges to our pipe industry. Although tube prices also peaked, the price increase was higher for hot-rolled coils than for welded tubes. Most forecasts now predict that prices for hot-rolled coils will settle down and increase by a maximum of another 80 UDS by 2023. But demand for pipes is also calming down with similar effects on prices. Prices for commodity pipes in Europe are currently around 830 USD/tonne, resulting in a value added of only 210 USD/tonne at most. Only the US market is still quite demanding at a high price level. OCTG pipes, which have a much higher material requirement, are traded at prices of about 3,000 to 4,000 USD/tonne in the USA.

Further opportunities are expected as new pipeline networks need to be built to follow oil and gas logistics as the war in Russia has made some of the existing pipeline system obsolete. Transporting oil and gas by pipeline is by far cheaper and more environmentally friendly than transporting LNG by ship.

Logistics costs have only recently fallen to normal levels, reducing supply bottlenecks for the steel industry.

Another challenge arises if policies to prevent climate change, such as the additional carbon costs agreed by the European Union, are not introduced in a balanced way. These impacts may also cause industries that consume a lot of energy to move to regions with lower costs. The confidence to compete on the world market with these additional costs in the future is fading for some pipe manufacturers. Pipe mill infrastructure in terms of pipe mills and finishing lines as well as digitalisation and applied quality assurance systems also play an important role. Increasing importance is attached to agile management strategies in terms of customer benefits, process and product quality improvement as well as purchasing processes using "Industry 4.0" measures.

With a view to the return to normality, it can be seen that both plant manufacturers and technology suppliers are increasingly finding interesting business opportunities in this new market segment. Some technology suppliers have already reacted to this and expanded their product portfolio to include digital solutions.

The International Tube Association has organised several well-attended webinars in 2020, 2021 and 2022 to maintain the exchange within our industry. This year, in May 2022, "Engineered Tubes for the Automotive Industry" and in November 2022, along with the Tube India 2022 exhibition, a hybrid congress titled "Emerging Technology and Innovations in Pipe & Tube Industry" was successfully organised by the ITA Indian Chapter. It was great to meet both tube manufacturers and suppliers to the tube industry at our world's largest tube trade fair 'Tube Düsseldorf 2022' and the regional trade fair 'Tube India 2022' in Mumbai. The positive response to these events is a sign of the impressive optimism in our tube industry.

The high cost of energy is a major challenge for our industry. The prices for gas (Figure 1) and electrical energy (Figure 2) are causing dark clouds over our steel and tube industry.

The price of gas peaked at around USD 9.8 at the end of August 2022, i.e. about 250% higher than at the beginning of 2022. Since November 2022 (USD 6), the price of natural gas has risen again to around USD 7.5. Gas can only be transported over long distances by ships as LNG (liquefied natural gas), which requires expensive treatment compared to natural gas transported by pipeline. For the liquefaction around 10-25 % of the calorific value of the natural gas is consumed. Therefore, regions like North America benefit from much lower gas costs as they have their own gas resources that can be used directly as natural gas. Europe has benefited for many years from cheap Russian pipeline gas, but now and in the future Europe will have to rely on much more expensive LNG gas, which means a significant cost disadvantage of about 20% for energy-intensive industries such as the steel and pipe industries. It remains a major political challenge to secure that this cost disadvantage will be overcome to ensure European energy intensive industry to be again cost wise at eye level with the industry in other regions. To explore more of the own regional European gas resources may be a valid option hereto. Electrical energy, the other major source of energy for the steel and tube industry, has also seen massive price increases, peaking in Europe in August 2022 (€500) and increasing tenfold compared to January 2020 (€50)!

Since 22 August, the price of electrical energy has dropped to €150, but still remains three times higher than in January 2020 (about €50). Compared to Europe, electrical energy prices in the US are far lower, only about 30% of European prices. This price difference is another disadvantage for the energy-intensive European steel and pipe industry.

Pipe manufacturers buy hot-rolled coils, round billets or plates as input material for their production lines. More than 70 % of the total world pipe production, i.e. about 110 million tonnes/year, are welded pipes. Welded tube producers are highly dependent on hot rolled coil prices and to a lesser extent on plate prices. Average prices for hot-rolled coils started to spike in September 2020 (around USD 450) and peaked at USD 2,000 in September 2021. Since then, prices have fallen to around 620 USD throughout 2022. However, a further maximum price increase of 80 USD/tonne is expected again for 2023.

Steel plate prices rose to an average price of around USD 1,800/tonne in the first quarter of 2022 and are now trading at an average of around USD 1,000/tonne in November 2022 (Figure 3). Billet prices, used for seamless tubes have not risen nearly as much as hot rolled coil prices, yet these prices have also cooled from average 810 USD/tons to an average of around 500 USD/tonne (Figure 3). This price rally has posed major challenges for our tube industry. Although pipe prices also reached all-time highs, the price increase was higher for hot-rolled coils in particular than for welded pipes, leading to an erosion of pipe manufacturers' margins in many regions of the world (Figure 4).

If we look at the European pipe market as an example, so far about 20% of pipe imports have been served by Russia and the Ukraine. In the case of seamless pipes, the import share from Russia and Ukraine was even as high as 40%. These volumes need to be supplied by other tube and pipe producers. Russian shipments in 2022 will decrease by 34% on-year to 1.06 million tonnes, the RBC newspaper reports, citing a presentation from fund director Alexander Semenchishin. Domestic consumption in Russia is seen decreasing by 2% on-year in 2022 to 9.12 Mio. tons. As a result, pipe production will fall by 5.5% to 10.04 Mio. tons. Many regions of the world such as Europe and North America need to compensate their pipe and tube imports from Russia and Ukraine. As a result of the increased demand and the lower supply of pipes, pipe prices have risen by more than 50% compared to the previous year 2021 (Figure 4) Until the beginning of October, pipe prices were still holding at high levels, but in November fears are being voiced from many regions that demand for pipes is weakening, which has an immediate impact on prices. Only the US is still reporting a sustained high for pipes. The expected decline in pipe demand and its negative impact on prices seems to be slower than the decline in prices for the input materials hot-rolled coils, plates and round billets. This would allow some pipe producers to compensate for some of the margin losses they suffered when input material prices exploded. The world tube and pipe production after a slight recovery in 2021 of 5%, was maintaining its world production level at about 150 Mio. tons in 2022.

Anyhow substantial regional differences are reported. Whereas the rest of the world (-22%) and India (-14%) suffer from less production of tube and pipes, the USA, driven by a strong OCTG and construction market report major growth in production (Figure 6).

Due to the coronal pandemic, supply chains and freight costs were severely affected. This situation has now improved. The supply chain pressure index has improved significantly, from index values of 4 at the beginning of 2022, the index has returned to normal values of around 1 this November (Figure 7).

Freight rates have also returned to near normal rates (Figure 8). Global rates of USD 10,000 at the beginning of 2022 have now fallen back to around USD 3,000. Freight rates from China to Europe of 14,000 USD at the beginning of 2022 have settled down to freight rates of around 3,500 USD in October 2022. These are good news for the industry and contributes to the recovery of international trade.

Another good sign for our industry can be seen in the prognosis, that Inflation has passed its maximum and shall further decline until 2024. The affords of the central banks, especially these of the US FED, has stopped the galloping inflation and reversed the trend (Figure 9). Anyhow we hope that Morgan Stanley does not see the situation too optimistic.

In addition to the inflation rate, the producer price index is an important parameter, as it reflects the costs of the manufacturing industry. As Figure 10 shows, these costs vary greatly from region to region. Europe brings up the rear here due to the sharp rise in energy costs. As already explained, the USA has here compared to Europe a significant advantage of more than 22% due to cheap local energy. China's cost situation is particularly advantageous here but is certainly shaped by weak demand due to the corona lockdowns.

As already stated, one major driver of the tube and pipe market is the OCTG market representing about 51% of the world tube and pipe production. After Corona the industrial production has picked up and led to a sharp increase in energy consumption since 2021, so that supply has hardly been able to meet demand (Figure 11). Secondly, the geopolitical sanctions created a massive contraction of Russian production causing speculative price increases (Figure 12). It is anticipated that the Russian Oil production may be reduced by up to 25%.

The corona lockdown in Shanghai at the end of March 22 briefly eased the situation on the price front, as demand for energy fell noticeably as a result (Figure 13). According to Platts estimates, China’s April demand plummeted to 13.35 million Bbl/d, down 11.5% year-on-year, though recovering transportation demand may push May figures back above 14 million Bbl/d. At the peak of lockdown mandates, gasoline and diesel demand in coastal regions dropped by as much as 40%, with a grand total of 45 cities with some form of movement restrictions.

Since July 22 (120 USD/Bbl) the prices for oil went down until early October 22 (77 USD/Bbl). The oil and gas producing countries reduced the supply volumes to stabilize the energy prices leading to a price corridor between 80 to 93 USD/Bbl (Figure 11). The energy industry is booming, Aramco, the world's largest producer of fossil fuels, has become the world's most valuable company this first quarter 2022. Currently, there is no evidence that oil and gas producers are increasing supply to capture market prices. The USA anyhow, to soften the inflation, significantly increases the number of rigs from 531 in May 2021 to about 800 end of November 2022 (Figure 14).

Of these 784 rigs, 627 are dedicated for the extraction of oil and 155 for gas. The growth pattern has slightly calmed down, anyhow demand stays on high level. Efforts to reduce dependence on fossil fuels can hardly be successful in the short term and can only contribute to decoupling in the medium term. For our pipe industry, however, this means that high energy prices must be expected in the future as well. Luckily these analysts, who were anticipating another surge towards the USD130-140 per barrel range this summer 2022 were wrong, but prices around 80-90 USD are most probable. The investments to secure the energy supply will keep the demand and prices for tube products high (Figure 15).

In addition to exploration activities, the need to build new pipeline routes has also increased since the ban on Russian pipelines to Europe. In the wake of the attacks on the Northstream pipelines, which released very large quantities of methane as an environmental desaster, it can be expected that the standards for pipelines will become even more demanding. This development offers the manufacturers of large-diameter pipes > 406 mm OD opportunities for interesting business. The global construction market with about 5% of the global tube market presents another opportunity for pipe manufacturers with growth potential. A recent study published by Global Construction Perspective and Oxford Economics, entitled "Global Construction 2030", forecasts an 85% growth in global construction output to 15.5 trillion by 2030, with three countries, China, USA and India, leading the way and accounting for 57% of global growth alone. Europe, on the other hand, will reduce its pace of investment. There is room for additional production capacity for structural tubes, especially in India, to follow the market trend. The tube industry needs to further promote the benefits of tube applications and showcase the architectural perspectives (Figure 16). Tubular profiles are an ideal choice when visible structures are desired due to their varied shapes and closed cross-sections combined with smooth sides. Best mechanical properties and the possibility to bridge large spans are further highlights of tube profiles. The automotive market representing about 15% of the global tube market is a quite steady and reliable market. After the set back of the world car production in2020, and the supply chain challenges in 2021, the market will continue to grow at a rate of 2 %/year (Figure 17) with many interesting tube and pipe applications. The production level in 2020, which fell due to the Corona crisis, could only be increased slightly to around 77.2 million light vehicles worldwide in 2021 due to various challenges in the supply chain. According to IHS, the recovery process will take longer in the volume markets of Europe and North America. Future growth will take place primarily in Asia, especially in China. However, China could increasingly become a sales problem for the western automotive industry due to the American decoupling tendencies. However, the tendency to further reduce the weight of vehicles supports the trend towards the use of tubular products. The greatest potential for the use of tubular products (Figure 18) is seen in vehicle frames, followed by chassis and powertrains. Tube manufacturers need to enter new vehicle series with larger volumes to further expand their presence in the light vehicle industry.

The mechanical engineering market segment, which accounts for around 9% of world pipe production, has developed well in line with global GDP in recent years (Figure 19). During the financial- and corona crisis, the market was characterised by higher volatility with sharper declines and quick recoveries. In 2022, the current further recovery is slowed down by geopolitical circumstances. Asia, and China in particular, is the largest market for machinery purchases. Here, therefore, the decoupling intentions of the USA must be observed since these could become a game changer for the worldwide mechanical engineering industry. The USA and Europe continue to be significant sales regions as well. It remains noteworthy that the Chinese industry has taken the global lead in machinery sales since the Corona crisis. This market segment certainly has the greatest variety of tube products. Cylinder-, ball bearing- and turned part tubes, to name just a few prominent representatives of this market segment, certainly show good prospects for tube producers.

Most pipe and steel producers were able to report strongly improved economic figures for Q1 and Q2 in 2022 in the wake of the price increases. However, for European pipe producers, the additional CO¬¬2 costs agreed to be imposed by the European Community represent a major challenge. Confidence in being able to compete on the world market in the future with these additional costs is dwindling among some tube producers.

In general, there is enough production capacity to serve even the increased demand for tubes and pipes for all market segments. Raw material prices for the steel as well as the tube and pipe industry would seem to have peaked by the end of 2021.

Energy costs, however, remain high and climb even further since market interventions (e.g. OPEC plus) and warlike actions call free world trade into question. Further challenge may be imposed, if political measures to prevent climate change are not introduced in a balanced way, with possible consequences being the migration of high energy consuming industries to lower-cost regions. Nonetheless, if the balance of supply and demand within the tubes and pipes industry can be restored, price volatility can be expected to calm down. How long will it take, to realize the inflation target of 2% again? Tube plant infrastructure with respect to tube mills and finishing lines as well as applied quality assurance systems also plays a significant role. Tube and pipe producers who have used the corona pandemic to improve their productivity, flexibility and customer service, like introducing “Industry 4.0” measures, will benefit from such measures.

With an eye to the return to something like normal, it should be noted that plant builders and technology suppliers alike may find interesting business opportunities in this new market segment. Some technology suppliers have already reacted and enhanced their product portfolio with the addition of digital solutions.

It is good to realize, that besides the virtual exchange in our industry, such as the webinars organized by the International Tube Association (ITA) now again hybrid or even personal events for industrial exchange take place. The recent conference alongside Tube India 2022 this November under the headline ” Emerging Technology and Innovations in Pipe Tube Industry” was an excellent example hereto. It was great to meet tube producers as well as suppliers to the tube and pipe industry at our world largest tube and pipe show “Tube Düsseldorf 2022” and the regional show “Tube India 2022” in Mumbai.

Dr. Gunther Voswinckel