Page 17 - ITAtube Journal 1 2024

P. 17

Market information

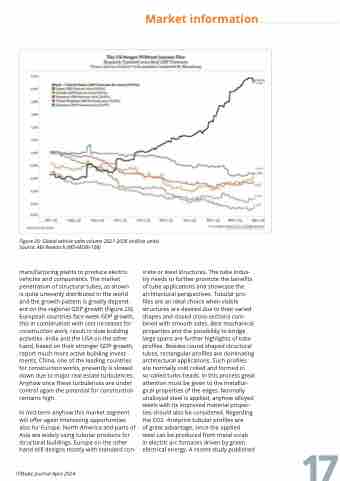

Figure 20: Global vehicle sales volume 2021-2026 (million units) Source: ABI Research (MD-MOBI-108)

manufacturing plants to produce electric vehicles and components. The market penetration of structural tubes, as shown is quite unevenly distributed in the world and the growth pattern is greatly depend- ent on the regional GDP growth (Figure 20). European countries face week GDP growth, this in combination with cost increases for construction work, result in slow building activities. India and the USA on the other hand, based on their stronger GDP growth, report much more active building invest- ments. China, one of the leading countries for construction works, presently is slowed down due to major real estate turbulences. Anyhow once these turbulences are under control again the potential for construction remains high.

In mid-term anyhow this market segment will offer again interesting opportunities also for Europe. North America and parts of Asia are widely using tubular products for structural buildings. Europe on the other hand still designs mostly with standard con-

ITAtube Journal April 2024

crete or steel structures. The tube indus- try needs to further promote the benefits of tube applications and showcase the architectural perspectives. Tubular pro- files are an ideal choice when visible structures are desired due to their varied shapes and closed cross-sections com- bined with smooth sides. Best mechanical properties and the possibility to bridge large spans are further highlights of tube profiles. Besides round shaped structural tubes, rectangular profiles are dominating architectural applications. Such profiles are normally cold rolled and formed in so-called turks-heads. In this process great attention must be given to the metallur- gical properties of the edges. Normally unalloyed steel is applied, anyhow alloyed steels with its improved material proper- ties should also be considered. Regarding the CO2 -footprint tubular profiles are

of great advantage, since the applied

steel can be produced from metal scrab in electric arc furnaces driven by green electrical energy. A recent study published

17