Page 21 - ITAtube Journal 1 2023

P. 21

Technical Papers

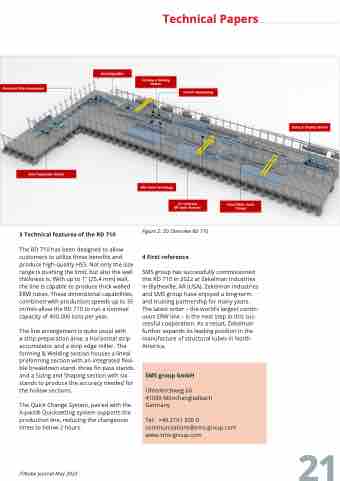

3 Technical features of the RD 710

The RD 710 has been designed to allow customers to utilize these benefits and produce high-quality HSS. Not only the size range is pushing the limit, but also the wall thickness is. With up to 1” (25.4 mm) wall, the line is capable to produce thick walled ERW tubes. These dimensional capabilities, combined with production speeds up to 35 m/min allow the RD 710 to run a nominal capacity of 400.000 tons per year.

The line arrangement is quite usual with

a strip preparation area, a horizontal strip accumulator and a strip edge miller. The forming & Welding section houses a lineal preforming section with an integrated flexi- ble breakdown stand, three fin pass stands and a Sizing and Shaping section with six stands to produce the accuracy needed for the hollow sections.

The Quick Change System, paired with the X-pact® Quicksetting system supports the production line, reducing the changeover times to below 2 hours.

Figure 2: 3D Overview RD 710

4 First reference

SMS group has successfully commissioned this RD 710 in 2022 at Zekelman Industries in Blytheville, AR (USA). Zekelman Industries and SMS group have enjoyed a long-term and trusting partnership for many years. The latest order – the world’s largest contin- uous ERW line – is the next step in this suc- cessful cooperation. As a result, Zekelman further expands its leading position in the manufacture of structural tubes in North America.

ITAtube Journal May 2023

21

SMS group GmbH

Ohlerkirchweg 66

41069 Mönchengladbach Germany

Tel: +49 2161 350 0 communications@sms-group.com www.sms-group.com