Page 18 - ITAtube Journal 1-2021

P. 18

Technical Papers

18

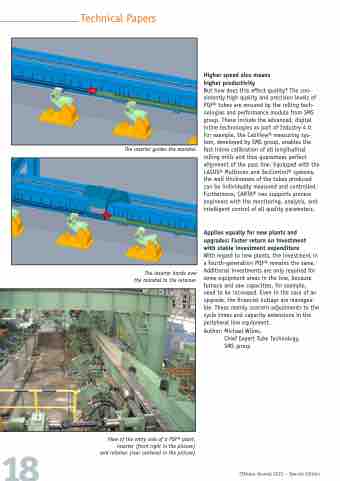

View of the entry side of a PQF® plant: inserter (front right in the picture) and retainer (rear centered in the picture)

The inserter guides the mandrel.

Higher speed also means

higher productivity

But how does this effect quality? The con- sistently high quality and precision levels of PQF® tubes are ensured by the rolling tech- nologies and performance module from SMS group. These include the advanced, digital inline technologies as part of Industry 4.0: For example, the CaliView® measuring sys- tem, developed by SMS group, enables the fast inline calibration of all longitudinal rolling mills and thus guarantees perfect alignment of the pass line. Equipped with the LASUS® Multiscan and SecControl® systems, the wall thicknesses of the tubes produced can be individually measured and controlled. Furthermore, CARTA® neo supports process engineers with the monitoring, analysis, and intelligent control of all quality parameters.

Applies equally for new plants and upgrades: Faster return on investment with stable investment expenditure

With regard to new plants, the investment in a fourth-generation PQF® remains the same. Additional investments are only required for some equipment areas in the line, because furnace and saw capacities, for example, need to be increased. Even in the case of an upgrade, the financial outlays are managea- ble. These mainly concern adjustments to the cycle times and capacity extensions in the peripheral line equipment.

Author: Michael Wilms,

Chief Expert Tube Technology,

SMS group

The inserter hands over the mandrel to the retainer.

ITAtube Journal 2021 – Special Edition