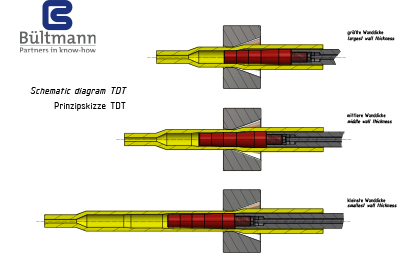

Tailor Drawn Tubes (TDT)

Against the background of increasing requirements for lower weights in the

automotive industry, the TDT technique becomes more and more important when

producing tubes.

The methods for the production of these special tubes known up to now, can only be

applied experimentally and are therefore very labour-intensive.

The increased demands for narrow tolerances can with difficulties only be fulfilled by

the current technical possibilities. Furthermore it is not possible to achieve a „steady“

process reliability when basing on the today’s technology.

Due to the numerous influencing parameters in the TDT drawing technology, the tube

drawing process applied today will very soon reach its technical limits.

An intensive development work and positive practical experience enable BÜLTMANN

to assist their customers in combining theory and practice. The patented TDT

Production System make BÜLTMANN in conjunction with the well-tried BÜLTMANN

draw bench technology can now be implemented in the tube production industry.

When developing the TDT tube drawing technology BÜLTMANN attached greatest

importance to the possibility to use the technological components which have already

been used for other applications.

In order to achieve very narrow tolerances, especially in the transition zone of wall

thickness, and to ensure the necessary process reliability at the same time, a closed

control circuit is indispensable. This process control is assured by combining sensible

and very dynamically reacting drive systems and especially designed measuring

devices and process software.

When harmonizing both components a precise, reliable and user-friendly control of

the TDT process is possible (see the schematic diagram).

In addition to the necessary drawing equipment, BÜLTMANN is also offering a

complete process consulting service for the TDT applications.